Cut Maintenance Costs + Boost Productivity! UBL Clothes Folding Machine Maintenance Core: Oil Protection Guide

Alyssa/November 4,2025 Return

For businesses like clothing factories and e-commerce warehouses that rely on bulk packaging, stable equipment operation is key to ensuring productivity. As a frequently used smart packaging device, the UBL Clothes Folding Machine’s core moving parts—such as chains, guide rails, and gears—are prone to wear from long-term high-speed operation. They may also rust and jam when exposed to air and moisture, which not only reduces folding efficiency but also increases maintenance costs and delays order delivery.

In fact, simple oiling maintenance can solve these problems, saving both money and hassle. Choosing the right lubricant is the foundation. Prioritize industrial-specific anti-rust lubricants—no need for complex models. They’re compatible with the UBL folding machine’s metal parts, reducing friction and wear while forming a protective film to block moisture.

The operation steps are easy to follow, and enterprise employees can do it themselves:

- Stop the machine and unplug the power. Wipe the surface of the parts thoroughly with a dry cloth to remove dust, fabric fibers, and other residues. This prevents impurities from mixing with oil and affecting maintenance results.

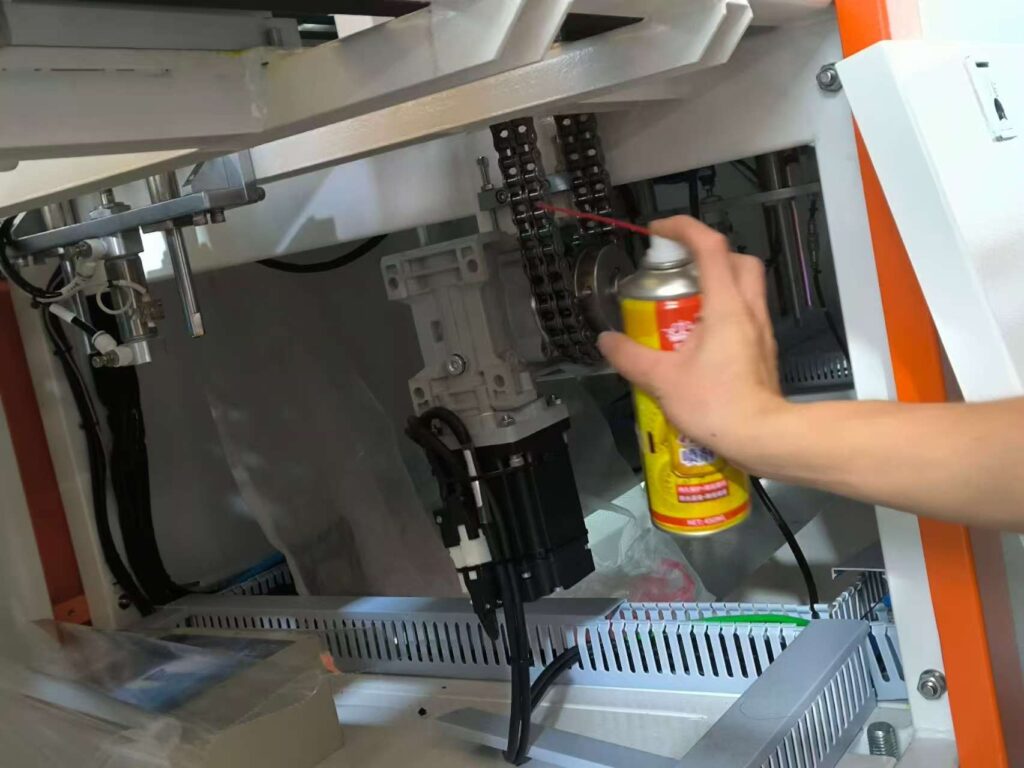

- Use a brush or dropper to apply a thin, even layer of oil to key moving parts like chains, guide rails, and gears. Avoid over-applying, as this can attract dust and cause dirt buildup.

- After oiling, start the machine and let it run idle for 3-5 minutes. This allows the lubricant to fully seep into gaps, ensuring every friction surface is covered.

It’s recommended to adjust the maintenance cycle based on usage frequency: once every 3-5 days during high-load production, and once a week under normal working conditions. Sticking to regular oiling maintenance not only prevents the machine from jamming and rusting but also extends the UBL Clothes Folding Machine’s service life. It maintains stable folding efficiency, reduces downtime for repairs, helps businesses cut long-term maintenance costs, and ensures steady productivity output.

What efficient maintenance tips do your factories use for smart packaging equipment? Feel free to share and exchange ideas in the comments—let’s improve the cost-effectiveness of equipment use together!