How Cosmetic Factories Lose $10,000+ Per Season From Skincare Gift Box Cartoning Errors

Alyssa/ December 21, 2025 Return

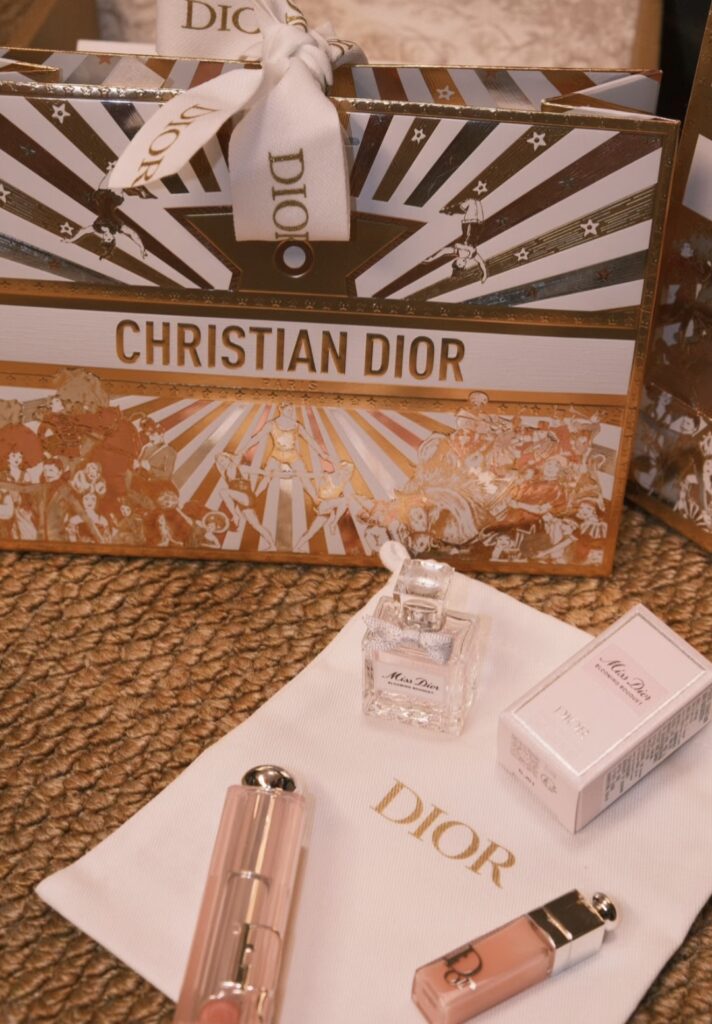

Gift box packaging is where cosmetic profits are most fragile

In cosmetic factories, individual skincare products are usually well controlled.

Bottles are filled correctly.

Labels are approved.

Inner packs are checked.

Problems often happen when products are combined into gift boxes.

Skincare gift sets are not just packaging.

They are promises to retailers and consumers.

When cartoning goes wrong, the product does not get partially accepted.

It gets rejected.

Why skincare gift sets are extremely sensitive to cartoning mistakes

One missing item makes the whole gift box unsellable

A skincare gift set is a fixed combination.

Cleanser.

Serum.

Cream.

If one item is missing or duplicated, the set is no longer valid.

Retailers do not fix gift boxes.

They return them.

That means one small cartoning mistake turns into a full-box loss.

Manual cartoning struggles with seasonal SKUs

Cosmetic gift sets change frequently.

Holiday editions.

Limited designs.

Market-specific bundles.

When workers manually load different products into boxes, mistakes happen under time pressure.

Wrong item.

Wrong size.

Wrong version.

During peak seasons, these mistakes increase.

What cartoning errors really cost cosmetic factories

A realistic loss scenario

Let’s look at a common situation.

A factory produces 5,000 skincare gift boxes for a holiday promotion.

If only 2 percent of boxes are incorrectly packed, that is 100 unsellable gift sets.

With an average wholesale value of $80 per set, that is $8,000 in product value at risk.

Add rework labor, delayed delivery, and possible retailer penalties, and the loss easily exceeds $10,000 for a single run.

The bigger loss is missing the selling window

Gift boxes are time-sensitive.

If delivery is delayed because of repacking, the promotion window closes.

At that point, even perfect products may no longer sell at full price.

This is how packaging errors quietly destroy margin.

Why these problems get worse as order volume increases

Scale multiplies complexity, not control

When volumes increase, factories often add people, not systems.

More workers means more variation.

Manual cartoning cannot guarantee that every box follows the same rule, especially when SKUs change often.

This is why many cosmetic factories experience stable production but unstable gift set quality.

How our automatic cartoning machines prevent gift box losses

Our machines control set composition, not just box closing

We design automatic cartoning machines specifically to handle multi-item cosmetic gift sets.

Each box follows predefined loading logic.

Correct product combination.

Correct sequence.

Correct count.

The machine does not rely on memory or experience.

Automation protects peak-season output

Automatic cartoning keeps gift box accuracy stable even during long shifts and peak demand.

Factories can run promotions without worrying about configuration drift.

This protects both revenue and brand relationships.

Is automatic cartoning right for your cosmetic gift sets

If your factory produces skincare sets, limited editions, or seasonal gift boxes, manual cartoning becomes a risk multiplier.

The question is not whether mistakes happen.

The question is how many boxes become unsellable before the problem is noticed.

Talk to us about your cosmetic gift box packaging

Tell us what products go into your sets, how often SKUs change, and your seasonal volume.

We can help you evaluate whether automatic cartoning fits your packaging line and reduces loss risk.

Our cartoning solutions are designed to protect high-value packaging.

| Product & Scenario | Search Intent Keywords | Factory Loss | Why It Happens | How Our Cartoning Machine Helps |

|---|---|---|---|---|

| Skincare gift sets with multiple items | cosmetic gift box packing errors | Unsellable gift boxes returned by retailers | Manual product selection under time pressure | System-controlled product combination loading |

| Seasonal cosmetic promotions | holiday cosmetic gift packaging problems | Missed selling window and margin loss | Rework delays caused by packing mistakes | Stable automated cartoning during peak demand |

| High-value cosmetic SKUs | cosmetic packaging quality control | High product value lost per error | Human-dependent packing variability | Repeatable cartoning logic reduces risk |