How Toy Factories Lose $5,000–$12,000 Per Month From Cartoning Mistakes as Blind Box Orders Grow

Alyssa/ December 20, 2025 Return

Cartoning mistakes are the fastest way to lose money in toy factories

In toy factories producing blind box toys or small toy sets, the front end usually runs smoothly.

Injection molding is stable.

Assembly is clear.

Individual items are packed correctly.

Problems often appear at the cartoning stage.

This is where different toy styles, colors, or characters must match the carton configuration exactly.

When cartoning is done manually, mistakes don’t look serious at first.

But once orders scale, those mistakes become expensive very quickly.

Why blind box toys are especially sensitive to cartoning errors

One wrong toy in a box is not a small mistake

Blind box products depend on accuracy.

Collectors expect randomness within rules.

Retailers expect the correct ratio and configuration.

If a carton that should contain mixed styles is filled incorrectly, the issue is not cosmetic.

Customers complain.

Retailers escalate.

Compensation follows.

A single wrong configuration can turn into hundreds of customer complaints online.

Manual cartoning makes style mixing hard to control

Blind box production usually involves many SKUs.

Different characters.

Different colors.

Limited editions.

When workers manually load toys into cartons, they rely on memory and speed.

Under pressure, styles get mixed incorrectly or repeated too often.

This is how factories end up shipping cartons that do not match the promised configuration.

What cartoning mistakes really cost toy factories

Customer complaints turn into direct cash loss

Let’s look at a realistic scenario.

A toy factory ships 10,000 blind box units per day.

If only 0.5 percent of cartons contain incorrect toy combinations, that is 50 problematic cartons every day.

Each issue may require refunds, reshipping, or compensation to distributors.

Over a month, these small mistakes easily add up to five to twelve thousand dollars in direct losses.

And this does not include brand damage or lost future orders.

The hidden cost is lost trust, not just money

Toy buyers remember mistakes.

Once a retailer sees repeated configuration issues, they slow down reorders or reduce volume.

This is how cartoning errors quietly cap growth, even when demand exists.

Why losses increase as blind box orders scale

Volume multiplies the same error

When orders double, the risk does not stay the same.

The same small error rate now affects twice as many cartons.

What used to be manageable turns into constant customer service pressure and compensation costs.

Many toy factories only realize this when blind box orders suddenly take off.

How our automatic cartoning machines prevent these losses

Our cartoning machines control toy configuration, not just box filling

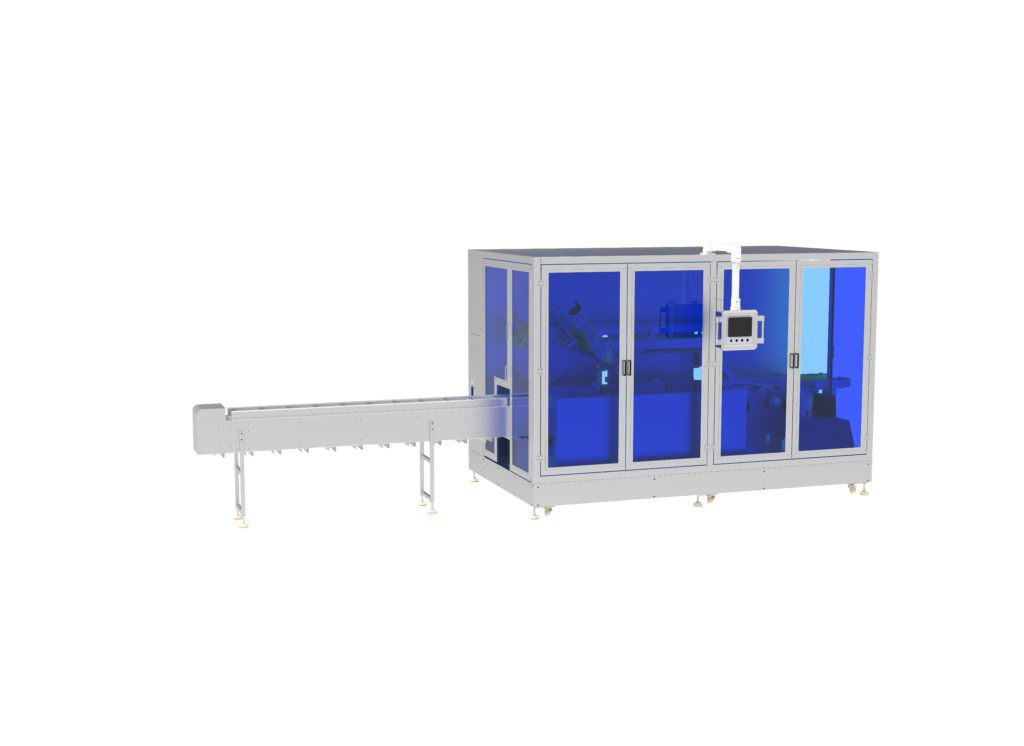

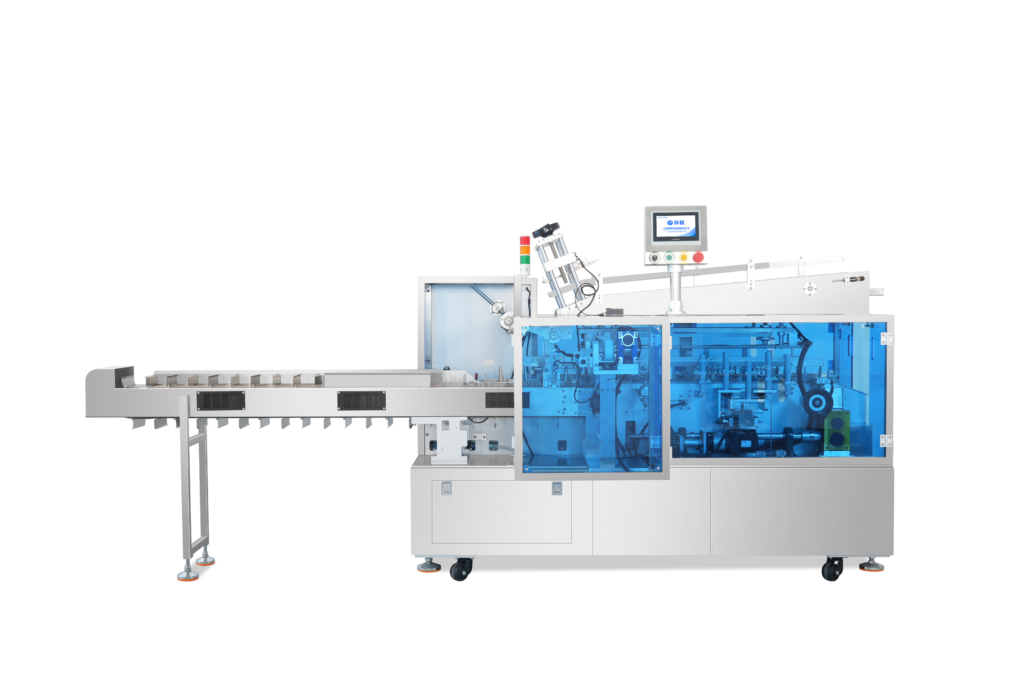

We design automatic cartoning machines for toy factories where configuration accuracy matters.

The goal is to ensure that cartons follow predefined loading rules.

Each carton receives the correct number and combination of toy units.

The process is driven by system logic, not human memory.

This significantly reduces wrong-style and wrong-ratio shipments.

Automation stabilizes output during peak seasons

Toy orders spike before holidays and promotions.

Automatic cartoning keeps carton configuration stable even during long shifts and high output periods.

Factories no longer rely on overtime and manual checks to protect accuracy.

Is automatic cartoning right for your toy factory

If your factory produces blind box toys, collectible figures, or small toy sets with multiple styles, manual cartoning becomes a risk multiplier.

The question is not whether mistakes happen.

The question is how many times the same mistake repeats before it costs more than fixing the process.

Talk to us about your toy product and carton setup

Tell us how many styles you run, how cartons are configured, and your daily output.

We can help you evaluate whether automatic cartoning fits your toy packaging line and where losses may already be happening.

Our cartoning solutions are built to protect accuracy as volume grows.

| Product & Scenario | Search Intent Keywords | Factory Loss | Why It Happens | How Our Cartoning Machine Helps |

|---|---|---|---|---|

| Blind box toys with multiple characters | blind box packaging errors, wrong toy in box | Customer complaints and compensation costs | Manual style selection under speed pressure | System-controlled configuration loading |

| High-volume promotional toy orders | toy packaging mistakes high volume | Monthly refund and reshipment losses | Error rate multiplies as output increases | Stable automatic cartoning cycles |

| Retail toy distribution programs | toy retailer packaging requirements | Reduced reorder volume due to trust issues | Inconsistent carton configurations | Repeatable and documented cartoning process |