The Manual Packaging Trap — The Disaster You Don’t See Until It’s Too Late

Alyssa/ November 28, 2025 Return

Have you ever walked into your packaging area early in the morning and felt everything seemed peaceful? Workers chatting, cartons neatly stacked, the folding machine warming up, the cartoning machine humming quietly, the bagging machine waiting to start the day. On the surface, it looks fine—almost comfortable. But what if I told you that this “quiet” is exactly the moment when your factory begins losing money?

Because manual packaging doesn’t show its damage immediately.

It bleeds you slowly.

Silently.

Like a leak behind a wall you don’t see—until the whole structure collapses.

It begins when the folding machine pauses for half a second.

Nobody notices.

It happens again two minutes later.

Still nobody notices.

But your output? It notices.

Then a worker folds a carton slightly crooked.

They correct it.

Then they correct another one.

And another one.

Each correction looks harmless—but each one is literally money leaving your pocket.

Then the cartoning machine jams on an imperfect edge.

Everything stops.

Your supervisors run over.

Workers scramble.

Production falls behind by five minutes.

Five minutes here, five minutes there—

by the end of the week, you’ve lost hours.

But because nothing exploded, nobody treats it like a real problem.

That’s the trap.

Manual packaging doesn’t fail loudly. It fails quietly—until the damage becomes irreversible.

Maybe you’ve seen this pattern:

Your workers look more tired every week.

They fold slower after lunch.

Their hands shake during long shifts.

They become scared of the cartoning machine because it jams so often.

The bagging machine seals well in the morning, but badly at night.

Your error rate grows, but you don’t realize it’s tied to human fatigue.

Or maybe you’ve seen this:

A worker calls in sick.

Another one resigns.

One new guy starts but can’t keep up with the folding machine speed.

Suddenly your entire packaging line collapses because it depends too much on people—people who are tired, stressed, overwhelmed, or simply human.

And here is the truth that hurts the most:

Manual packaging problems do not appear on the day they begin. They appear weeks later in your profit report.

You don’t notice when:

your packaging line slips 1% in speed

your workers slow down at 4 PM

your folding machine hesitates during high load

your cartoning machine rejects slightly crooked boxes

your bagging machine produces inconsistent seals

But your bank account notices.

Your waste rate notices.

Your customers notice.

Factories in the US and UK are learning this the hard way.

Many used manual packaging because “it seemed cheaper,” but eventually found out that manual packaging is the most expensive choice of all.

Here’s how the invisible damage grows:

1 hour of slow manual packaging per day → 7 hours per week

7 hours per week → 28 hours per month

28 hours per month → 336 hours per year

That’s two months of productivity lost.

Not because of machines failing—

but because of tiny, invisible human delays.

That’s when factories finally say:

“We can’t keep losing money like this.”

And that’s when they upgrade to automated packaging.

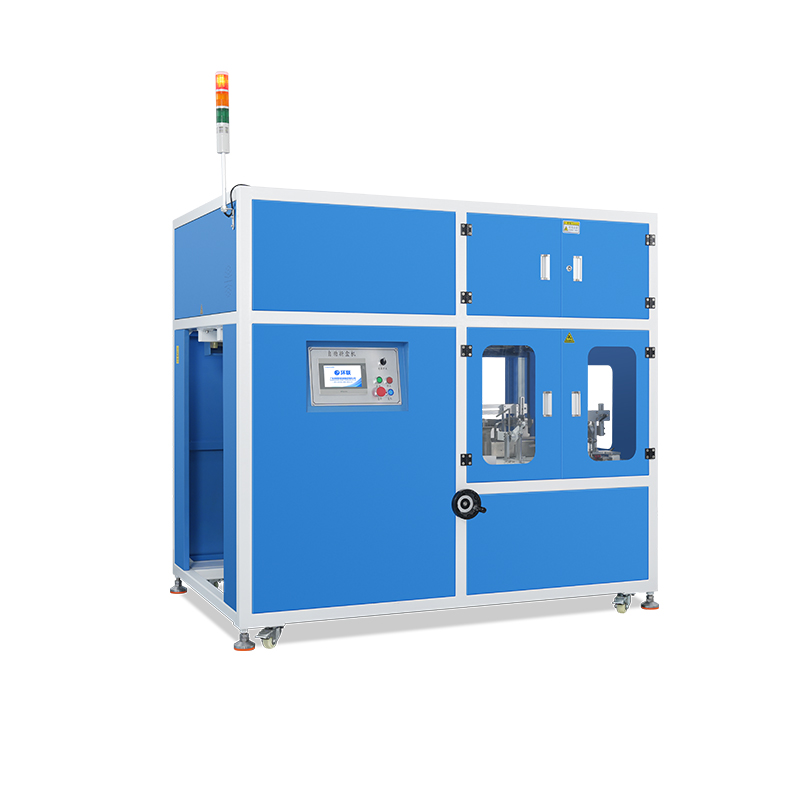

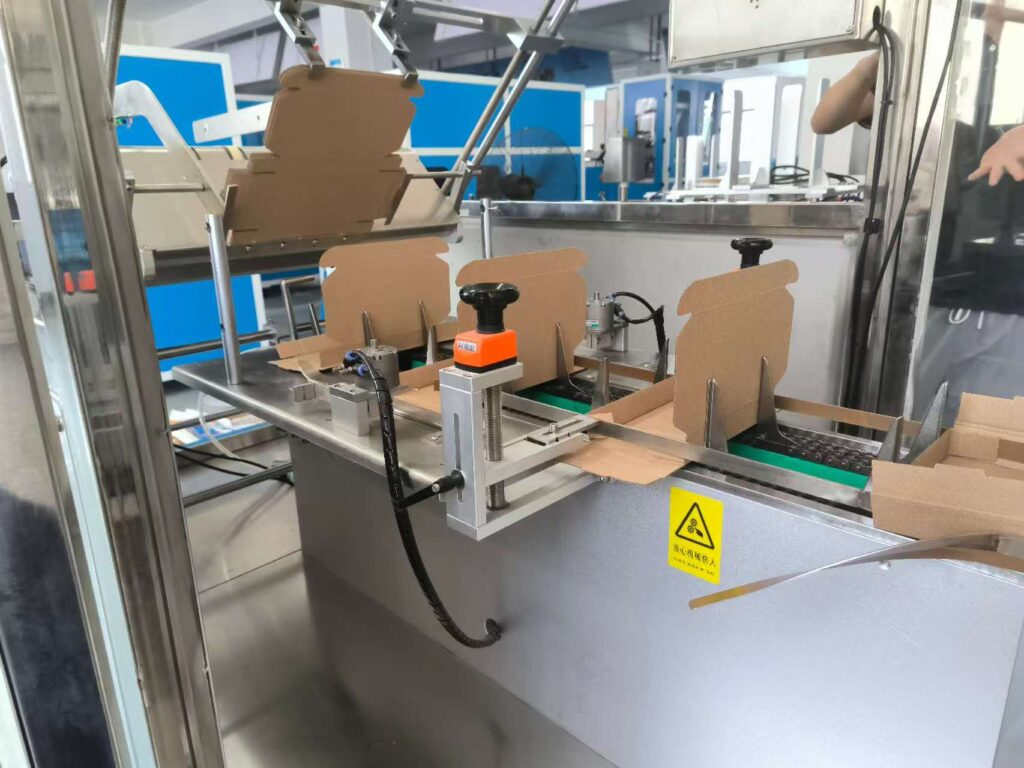

This is why UBL’s folding machines, UBL’s HL-Z15 cartoning machine, and UBL’s high-precision bagging machines are becoming the first upgrade many factories choose—not the last. Because these machines are not just faster. They eliminate thousands of micro-mistakes manual packaging creates.

UBL folding machines don’t slow down after lunch.

UBL HL-Z15 doesn’t choke on small imperfections.

UBL bagging machines seal perfectly whether it’s 8 AM or 8 PM.

They remove the human unpredictability from packaging—the part that kills your profit.

When factories automate:

Packaging becomes consistent.

Output becomes predictable.

Waste goes down immediately.

Complaints drop.

Profit finally stops leaking.

So let me ask you honestly:

Is your manual packaging slowly killing your factory without making a sound?

Tell me where it hurts—I can tell you exactly where the leak begins.