Why Do Hardware Factories Lose Control When Orders Get Bigger?

Alyssa/ November 29, 2025 Return

Why is it that hardware factories—big or small—always seem calm until the moment they reach the bagging stage? Screws are machined perfectly, metal parts come off the presses smoothly, connectors pass inspection, and everything seems ready for shipment. But the moment these items need to be counted, sorted, and bagged, the entire production rhythm suddenly collapses.

If you run a hardware factory, a fastener workshop, or an export business dealing with screws, nuts, bolts, metal clips, hinges, or mixed accessory kits, you’ve probably asked yourself more than once:

“Why does bagging become a disaster exactly when orders grow?”

Let’s look at what really happens.

The bagging station is supposed to be the “easy” step. But in the hardware industry, it’s the most dangerous bottleneck.

Metal parts are small, heavy, sharp, irregularly shaped, and available in thousands of specifications. One order may require 20 pieces per bag, the next requires 10 pieces + 1 bracket, the next requires mixed parts for an installation kit, and the next needs anti-rust bags for export.

Workers must:

count → confirm → match → check labels → open bags → avoid sharp edges → seal → repeat thousands of times.

And this is where the nightmare starts.

Picture this:

A worker has been counting screws for hours. Their fingers are sore, tiny parts keep slipping, some screws puncture the bags, labels get misplaced, quantities get mixed, and the metal dust starts to cling to every surface. The table becomes chaotic. Batches get confused. QC starts rejecting entire cartons because of wrong counts or mixed SKUs. And meanwhile, the order list keeps growing.

This is the moment the disaster becomes visible:

1 wrong screw → 1 wrong bag → 1 wrong box → 1 wrong shipment → 1 angry customer → 1 ruined contract.

It all starts with a bag that wasn’t filled perfectly.

The core problem (the WHAT) is very simple:

manual bagging cannot handle precision, quantity, or consistency in hardware manufacturing.

Humans cannot keep accurate counts after 6 hours.

Humans cannot maintain the same speed when parts are sharp or heavy.

Humans cannot avoid fatigue mistakes.

But hardware customers expect perfection—especially export clients, e-commerce buyers, and installation kit suppliers. If one bag has 19 screws instead of 20, the entire batch loses credibility. If screws poke through the polybag, the shipment gets rejected. If labels don’t match counts, the warehouse refuses the inventory.

So how do you stop this “bagging disaster” from destroying your schedule and reputation?

The solution isn’t more workers, more training, more overtime, or more checking.

The real solution is:

remove human error from the bagging process.

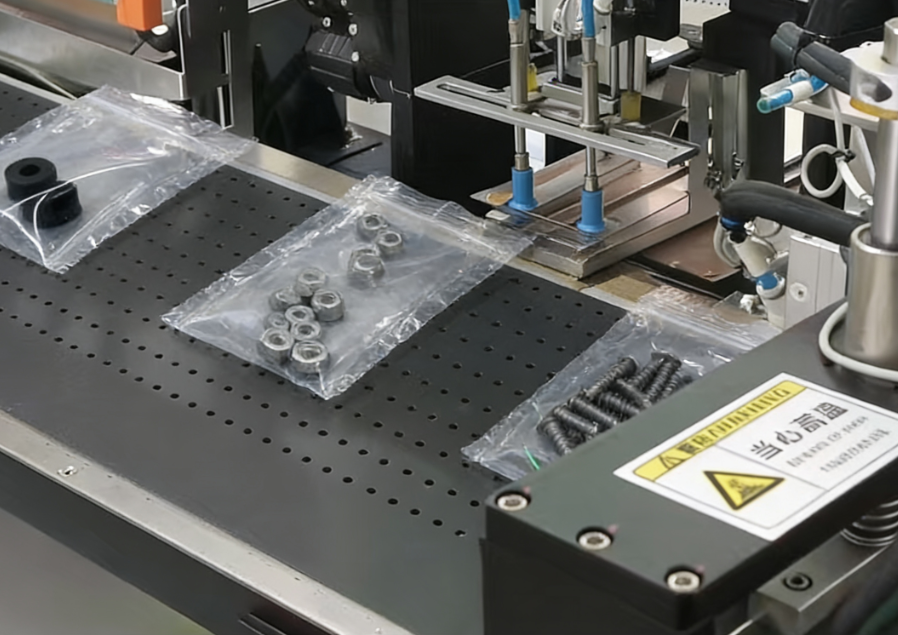

This is where UBL’s automatic bagging machine becomes the game changer for hardware factories.

UBL can:

- open bags automatically

- count pieces with electronic precision

- prevent mixed SKUs

- avoid bag punctures with controlled insertion

- seal firmly

- apply labels accurately

- process thousands of units consistently

It transforms a chaotic, exhausting, mistake-prone step into a clean, predictable, professional workflow.

Factories that switch to UBL describe the change like a weight lifted off their entire line:

“Our counting accuracy finally reached 100%.”

“No more returns because of wrong quantity.”

“We stopped losing customers over simple packaging errors.”

“Our workers no longer fear the bagging station.”

In the hardware world, consistency is everything.

A perfect bag equals trust.

A clean seal equals brand quality.

Accurate labeling equals export reliability.

And when your bagging is automated, your entire factory becomes faster and more stable.

So here’s the question for you:

Are your workers overwhelmed at the bagging station?

Do orders pile up because of counting and sorting?

Have you lost customers due to errors in hardware kits?

Does your factory slow down the moment SKUs increase?

If the answer is yes, then bagging isn’t your final step—it’s your biggest vulnerability.

And it may be time to upgrade to a system built for precision.

Tell me what hardware products you package—screws, bolts, nuts, mixed accessory kits, metal parts—and I’ll help you find the best UBL bagging solution for your factory.