How Snack Bar Factories Lose $3,000–$8,000 Per Month From Cartoning Mistakes as Orders Grow

Alyssa/ December 19, 2025 Return

Cartoning losses rarely show up on one invoice

Most snack bar factory owners don’t see cartoning losses clearly.

They don’t appear as a single big bill.

They appear as small problems, spread across weeks.

One short carton today.

One mixed flavor case tomorrow.

One customer claim next month.

By the time owners feel the pain, the money is already gone.

Why small cartoning mistakes become expensive fast

One missing bar is not one missing bar

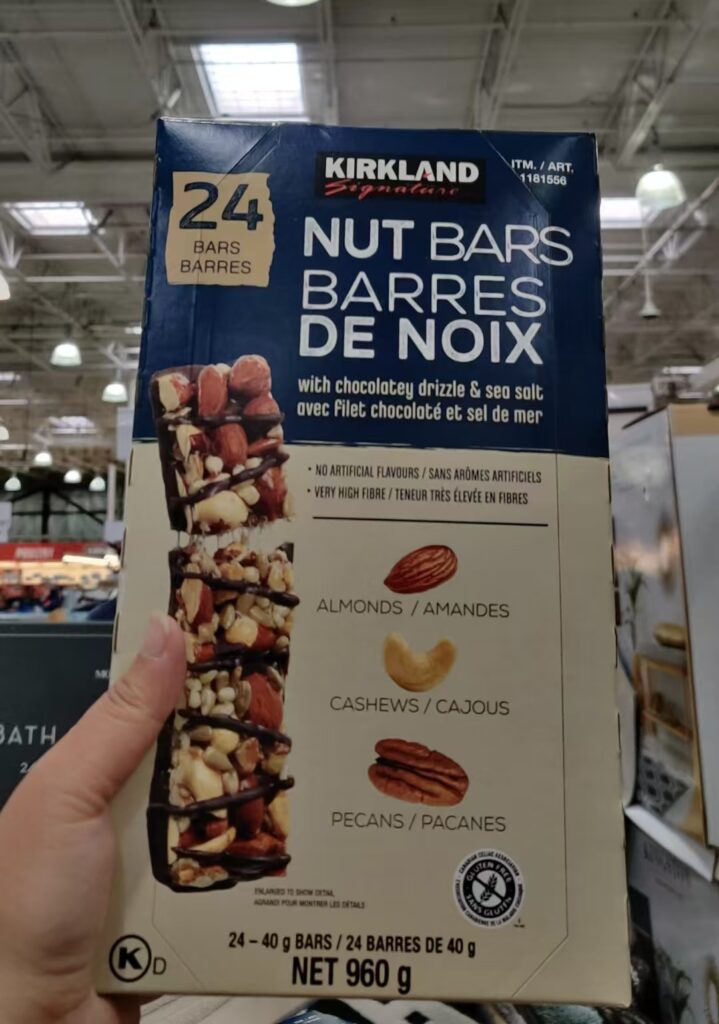

Let’s take a common example.

A factory packs 12-bar cartons.

Daily output is around 4,000 cartons.

If manual cartoning misses just one bar in 1 percent of cartons, that is 40 cartons per day with a short count.

Those cartons usually don’t get caught immediately.

They ship.

Now the cost is no longer one bar.

It becomes rework, claims, and credibility damage.

Over a month, this type of issue alone can quietly cost several thousand dollars.

Mixed flavors cost more than rework

Snack bar factories often run multiple SKUs.

When manual cartoning mixes flavors incorrectly, the problem escalates.

Retail customers don’t rework mixed cartons.

They reject them.

That means returns, disposal, and sometimes penalties.

One rejected pallet can easily cost two to three thousand dollars when you add logistics, labor, and lost product value.

Why losses increase as snack bar orders scale

Higher volume multiplies the same mistake

When daily output doubles, the risk doesn’t stay the same.

The same 1 percent error rate now affects twice as many cartons.

What used to be a small annoyance becomes a weekly financial hit.

This is why many snack bar factories feel that packaging problems suddenly appear when orders grow, even though nothing “changed” on the line.

Chargebacks turn mistakes into direct cash loss

For factories supplying retail programs, there is another cost.

Chargebacks.

A short pack or mixed SKU can trigger deductions that are not negotiable.

One chargeback may equal the profit of several days of production.

That is when owners start asking serious questions about cartoning control.

The hidden cost owners don’t calculate

Time spent fixing problems is real money

When cartoning errors happen, supervisors stop managing production and start fixing issues.

Lines slow down.

Schedules shift.

Extra checks are added.

This lost time rarely appears in reports, but it affects output every day.

Over time, this operational drag costs almost as much as the visible losses.

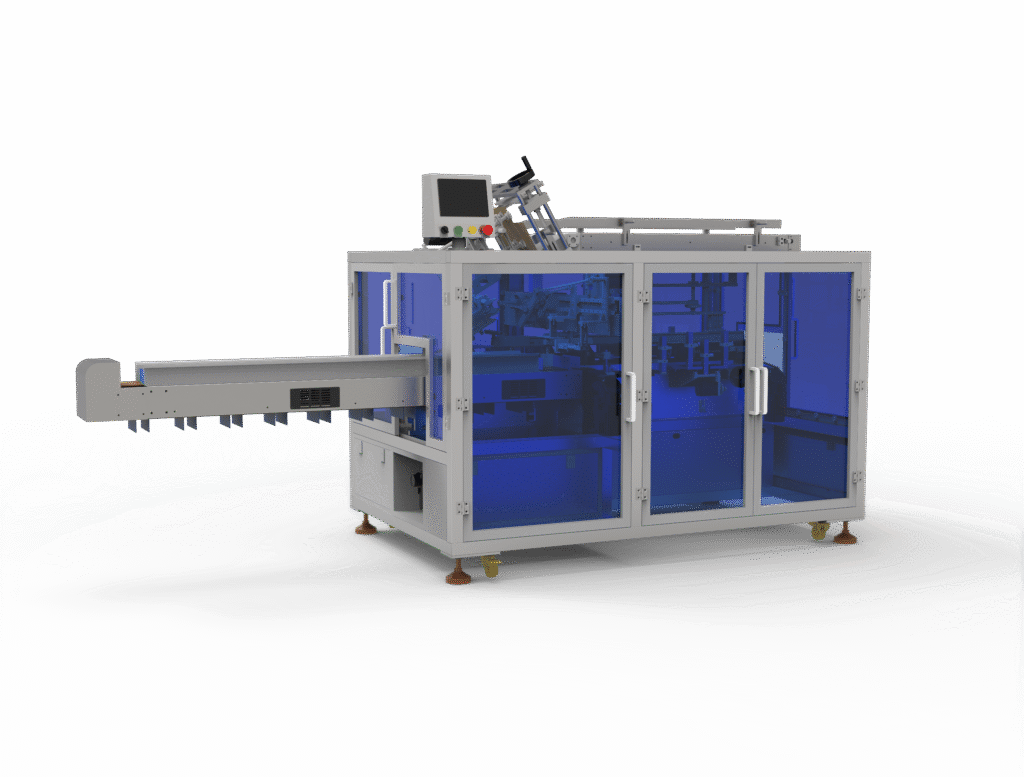

How our automatic cartoning machines stop these losses

We focus on preventing repeat mistakes, not fixing them later

Our automatic cartoning machines are built to remove variability from snack bar cartoning.

The goal is simple.

Make every carton follow the same process every time.

Consistent loading reduces short cartons.

Controlled positioning reduces mixed configurations.

Stable cycles reduce operator-dependent errors.

When mistakes stop repeating, losses stop multiplying.

Automation protects profit as orders grow

With automatic cartoning, increasing volume does not automatically increase risk.

Factories gain predictability.

Instead of wondering what shipped last night, owners know the process is controlled.

That confidence matters when retail programs expand.

Is cartoning automation worth it for your snack bar factory

If your factory is producing thousands of cartons per day, even a small error rate turns into real money.

The question is not whether mistakes happen.

The question is how often they repeat.

If the same mistake can happen again tomorrow, it will eventually cost more than fixing the root cause.

Talk to us about your product, pack count, and daily output

If you tell us your carton size, bars per pack, and daily volume, we can help you estimate how much cartoning mistakes may already be costing you.

Our automatic cartoning machines are designed to stop losses before they scale.

Reach out and let’s run the numbers together.

| Product & Scenario | Search Intent Keywords | Real Factory Loss | Why It Happens | How Our Cartoning Machine Helps |

|---|---|---|---|---|

| 12-bar snack bar cartons at high daily output | missing bars in carton, short pack snack bars | Dozens of short cartons ship every day, causing claims and rework | Manual loading misses units under speed pressure | Repeatable automatic loading reduces short-pack risk |

| Multi-flavor snack bar retail programs | mixed SKU packaging, wrong flavor in carton | One mixed pallet leads to rejection and disposal costs | Manual changeovers increase configuration mistakes | System-driven cartoning stabilizes SKU configurations |

| Scaling snack bar orders for retail customers | scale snack bar production, cartoning bottleneck | Small error rates turn into monthly cash loss as volume grows | Human-dependent cartoning repeats the same mistakes | Controlled cartoning cycles prevent error multiplication |

| Retail programs with chargeback penalties | retail chargeback packaging, packaging penalties food | Chargebacks directly reduce monthly profit | Inconsistent cartons trigger retail disputes | Stable cartoning output supports compliant shipments |