Why Wafer Biscuit Brands Lose Money When Cartoning Isn’t Stable — Even If Production Looks Fine

Alyssa/ December 27, 2025 Return

Wafer biscuits are not difficult to produce.

They are difficult to protect.

They are light.

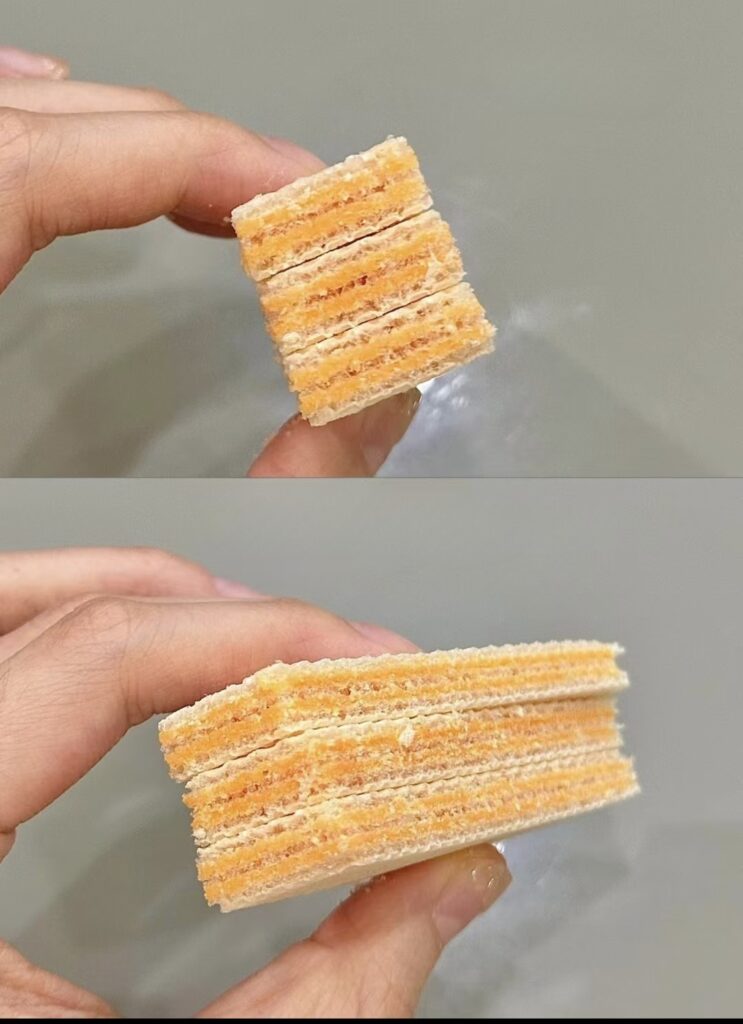

They are layered.

They crack easily.

And in many wafer factories, the biggest source of damage doesn’t happen in baking or wrapping.

It happens during cartoning.

Why Wafer Biscuits Are Especially Vulnerable in Secondary Packaging

Wafer structure amplifies small mechanical stress

Unlike solid biscuits, wafers are layered.

A small side pressure.

A slight drop.

An uneven push during insertion.

Any of these can cause internal cracks — even when the outer packaging looks normal.

That’s why wafer damage is often discovered after shipping, not on the line.

Cartoning is where protection becomes inconsistent

Primary packaging may be stable.

But when cartoning isn’t stable, protection becomes random.

Some cartons handle wafers gently.

Some don’t.

And inconsistency is what creates complaints.

What Cartoning Instability Looks Like on Wafer Lines

The line keeps running — but damage quietly increases

Unstable cartoning doesn’t always cause stops.

Instead, it causes:

uneven product positioning

inconsistent carton pressure

small shocks during insertion

variation from carton to carton

Operators may not see obvious defects.

But customers will.

Why Wafer Complaints Are So Expensive

Broken wafers destroy brand trust fast

When consumers open a wafer box and see broken pieces, they don’t blame logistics.

They blame the brand.

Even if the taste is fine, the experience is ruined.

This leads to:

refunds

negative reviews

retailer feedback

reduced shelf confidence

And wafer brands feel this faster than most snack categories.

The Hidden Cost of “Acceptable” Cartoning

Damage doesn’t scale linearly — it explodes

At low volume, instability creates manageable loss.

At scale, it multiplies.

A few cracked wafers per thousand become:

thousands of damaged units per week

consistent customer complaints

pressure from distributors

The factory may still ship.

But the brand starts paying for it.

Why Manual Handling Makes Wafer Damage Worse

More hands often mean more stress

When cartoning isn’t stable, factories often add labor.

More people adjusting products.

More manual correction.

More rework.

For wafers, this increases handling stress.

Instead of protection, you add more opportunities to break the product.

The Question Wafer Manufacturers Rarely Ask

The real question is not:

“How fast can this cartoning machine run?”

It is:

“Does it handle wafers the same way, every single time?”

Because wafers don’t fail from speed.

They fail from inconsistency.

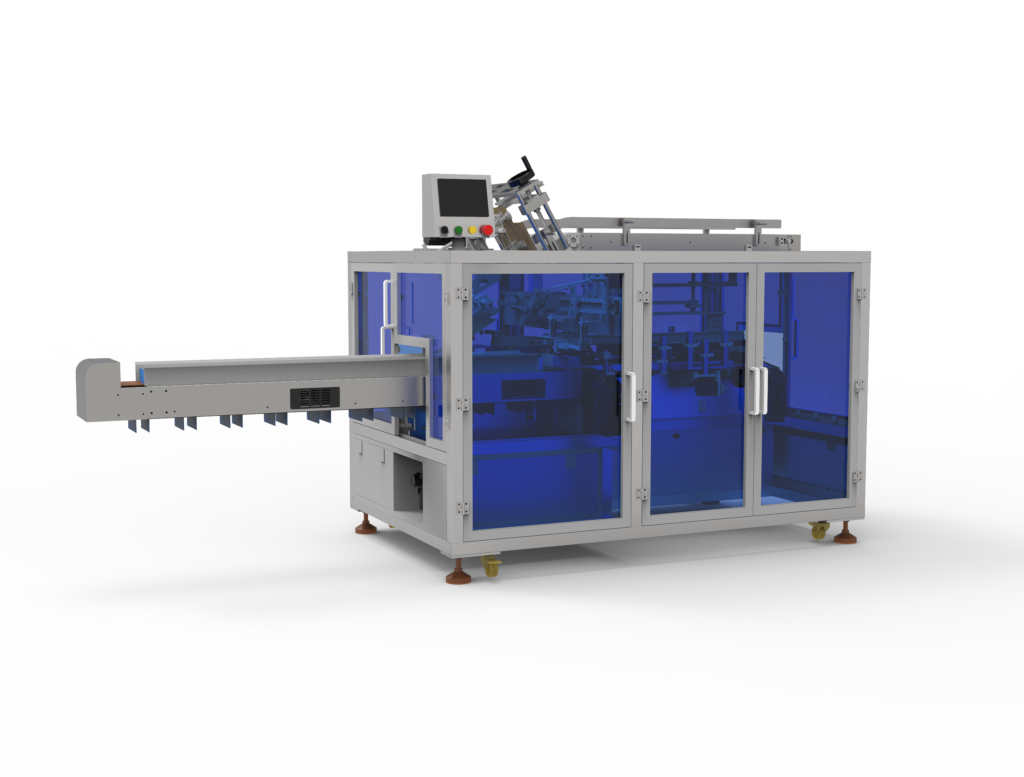

How We Design Cartoning Machines for Wafer Biscuit Secondary Packaging

We focus on secondary packaging only — cartoning — without touching food.

For wafer biscuits, stability means:

controlled product insertion without side pressure

consistent carton forming and closing force

smooth, repeatable motion across long runs

minimal variation between cartons

When cartoning becomes stable:

breakage drops

complaints decrease

retailer confidence improves

And wafer products arrive looking the way they should.

For Wafer Brands, Stability Is Product Protection

Unstable cartoning doesn’t just slow production.

It silently damages the product.

And the market notices long before the factory does.

Before Your Next Shipment, Ask Yourself This

Do wafer complaints increase even when production looks normal?

Do cracks appear randomly across shipments?

Are problems discovered by customers, not operators?

If yes, the issue may not be baking or wrapping.

It may be cartoning stability.

If you want, you can share your wafer format, carton type, and packing speed.

We can help you evaluate a more stable secondary cartoning approach that protects fragile products.

| Keyword | Search Intent | Category |

|---|---|---|

| wafer biscuit packaging machine | Commercial | Industry Equipment |

| wafer packaging line | Commercial | Industry Equipment |

| cartoning machine | Commercial | Core Equipment |

| automatic cartoning machine | Commercial | Machine Type |

| secondary packaging machine | Commercial | Application |

| cartoning machine stability | Informational | Core Pain Point |

| fragile food packaging | Informational | Scenario |