Why You Should Disconnect the Main Power and Dust-Proof Equipment During Long-Term Shutdowns

Alyssa/October 15,2025

For manufacturers relying on packaging equipment—from Huanlian’s automatic cartoning machines to high-speed bagging lines—long-term shutdowns (whether for maintenance, holidays, or production adjustments) pose hidden risks to equipment performance and lifespan. Two critical yet often overlooked steps—disconnecting the main power and implementing thorough dust-proof measures—are essential to avoiding costly damage and ensuring smooth restarts. These practices aren’t just routine maintenance; they’re investments in protecting your equipment’s integrity, especially for precision systems like those from Huanlian.

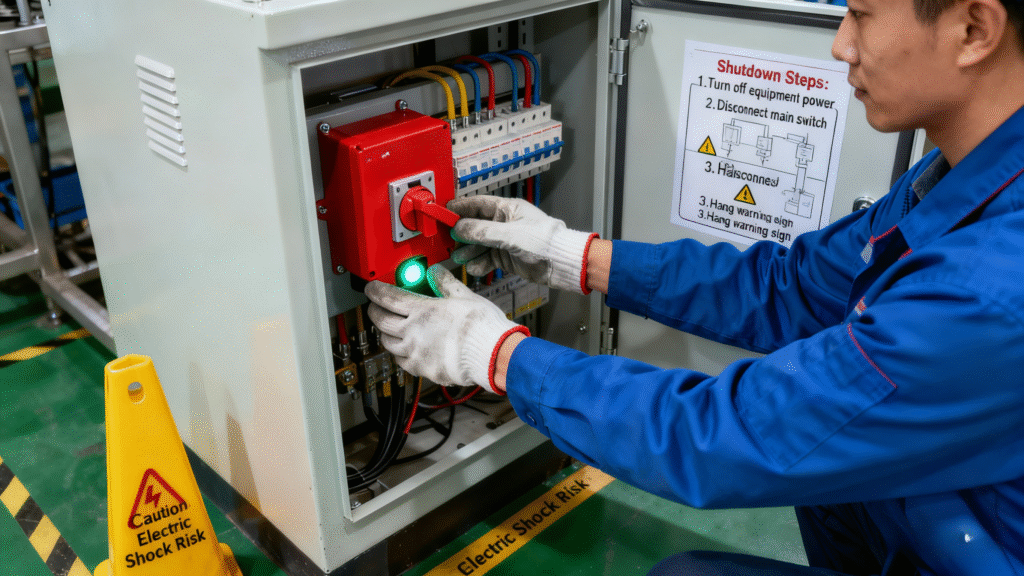

Disconnecting the main power goes beyond simple safety—it safeguards against electrical component degradation. Even in “off” mode, residual voltage can linger in circuits, capacitors, or control panels of equipment such as Huanlian’s HL-ZC-G2 high-speed cartoning machines. Over weeks or months, this low-level current can cause electrolysis in wiring, corrode connectors, or damage sensitive servo controllers—components that are core to the machine’s precision. For example, a Huanlian customer once skipped this step during a 3-month holiday shutdown; upon restart, the machine’s touchscreen failed due to capacitor damage, leading to a 5-day production delay and $2,000 in repairs. Additionally, power disconnection eliminates risks of voltage surges (common during grid instability) that could fry circuit boards, a threat that’s especially dangerous for automated lines with integrated sensors and PLC systems.

Dust-proofing is equally critical, as even fine particles can cripple packaging equipment. Food and beverage facilities, in particular, generate dust from ingredients like flour or sugar, while industrial environments accumulate lint, metal shavings, or ambient debris. For precision parts—such as the folding mechanisms of Huanlian’s HL-ZF30 fold-cover sealing machine or the labeling heads of its HLT-304 automatic labelers—dust buildup can cause jams, misalignments, or increased friction. Over time, this leads to premature wear: a dusty bearing might need replacement 6 months earlier than expected, and a dust-clogged sensor could misdetect packages, resulting in sealing errors. Huanlian recommends custom-fitted dust covers (made of breathable, static-resistant material) for its equipment, as generic covers may trap moisture—another hidden threat. For example, a snack factory that used plastic sheets to cover its Huanlian bagging line during a shutdown found mold growth on the conveyor belt, requiring deep cleaning and a 2-day delay to sanitize food-contact surfaces.

The process doesn’t end with power disconnection and covering. Before shutdown, it’s vital to clean equipment thoroughly—wiping down surfaces, removing residual product from hoppers, and lubricating moving parts (as per Huanlian’s maintenance guides) to prevent dust from adhering to greasy components. When disconnecting power, label all switches and circuits to simplify reconnection, and record the shutdown date for future reference. For dust-proofing, pay extra attention to entry points: seal cable openings with foam gaskets, cover air vents with HEPA filters (temporary ones work for short shutdowns), and wrap delicate parts like lens or sensors in anti-static cloths.

When it’s time to restart, reversing these steps systematically ensures safety and efficiency. Reconnect power gradually, checking for abnormal sounds or error codes on control panels (Huanlian’s machines feature diagnostic tools to flag issues early). Remove dust covers carefully, inspect for debris, and run a test cycle with dummy products to verify alignment—this avoids sudden jams when full production resumes.

Long-term equipment shutdowns don’t have to mean costly setbacks. By prioritizing main power disconnection and dust-proofing, you protect the precision, safety, and lifespan of your packaging lines—whether they’re Huanlian’s advanced systems or other critical machinery. These small, intentional steps ensure your equipment is ready to perform at its best when you need it most.

Newsletter Updates

Enter your email address below and subscribe to our newsletter