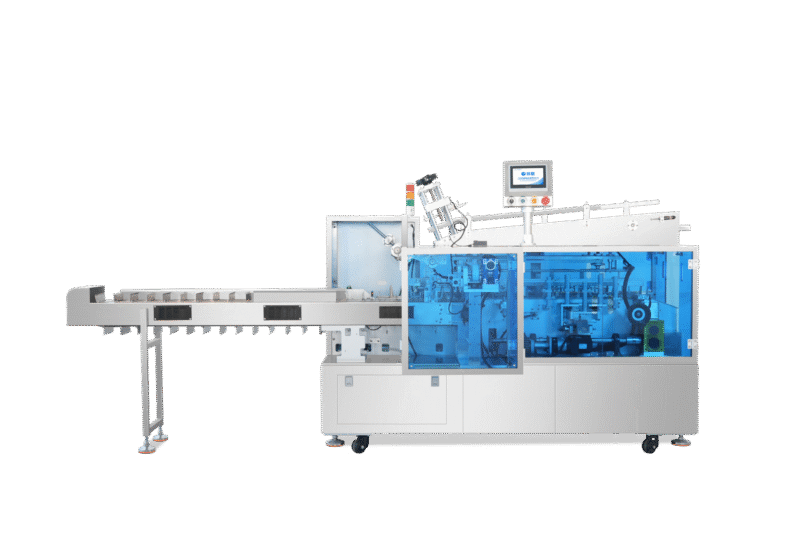

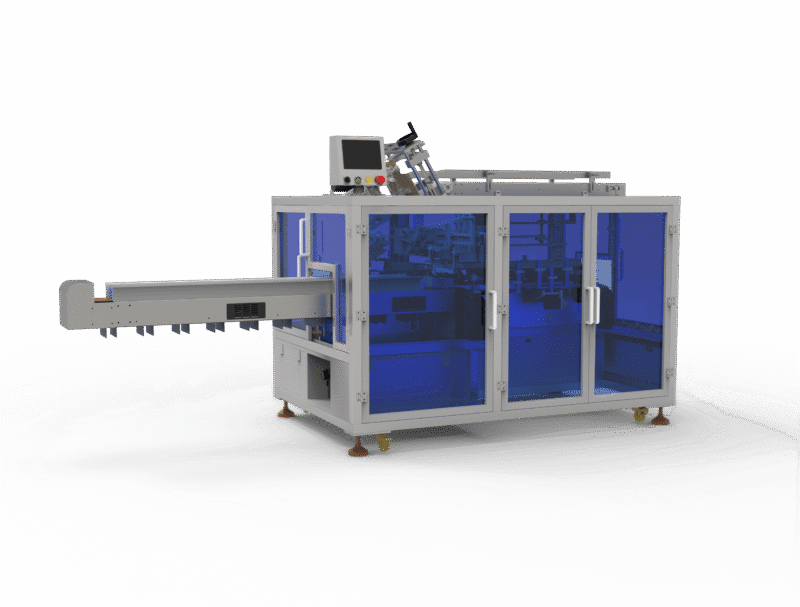

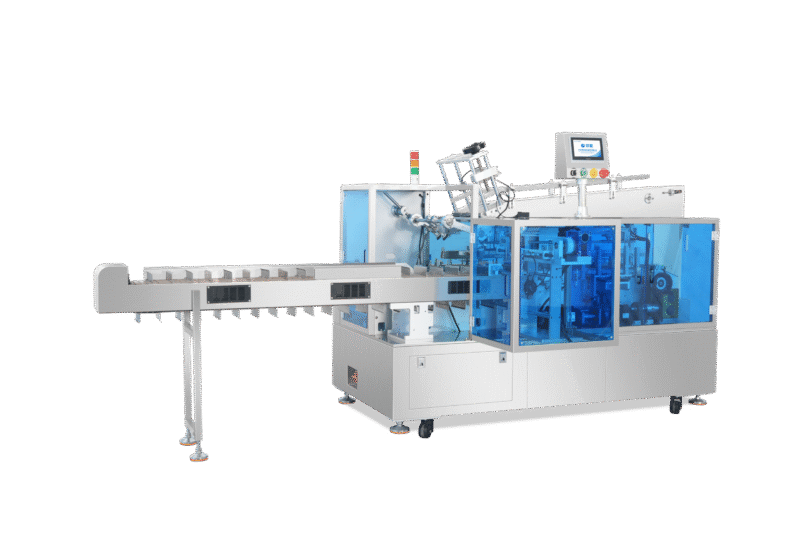

HL-ZC-01 Tuck End Box Automatic Cartoning Machine

Designed specifically for fast, reliable automatic product case packing — it handles the entire process: automatic case picking, opening, product loading, flap folding and sealing. It can run as a standalone unit, or seamlessly integrate with filling, labeling and conveying systems on your packaging line. Perfect for automated packaging needs across pharmaceuticals, food, household products and beauty industries.

Product Description

HL-ZC-01 Tuck End Box Automatic Cartoning Machine is designed for automatic packaging of products into tuck end paper cartons.

The machine integrates carton feeding, box opening, product insertion, and tuck end closing into one system, ensuring stable operation and consistent packaging quality. It is suitable for production lines that require reliable carton forming and automatic packaging.

HL-ZC-01 can work independently or be integrated into an automatic packaging production line.

Product Features

- Full-Automatic Case Packing Operation: Integrates automatic case picking, erecting, product loading and tuck sealing in one seamless process.

- High Stability & Continuous Operation: Ideal for medium-to-high volume production lines.

- Strong Compatibility: Quick changeover for different carton sizes; adaptable to various product formats.

- Complete Line Integration Capability: Can be combined with filling machines, labeling machines, checkweighers, conveyors and other equipment.

- Industry Versatility: Suitable for pharmaceuticals, food, cosmetics, household goods, electronics and other sectors.

Application

This tuck end box automatic cartoning machine is widely used in the following industries:

| Industry | Typical Application |

|---|---|

| Pharmaceutical | Pharmaceutical manufacturers have extremely high requirements for packaging quality and consistency. Fully automatic carton case packers can precisely control the case packing sequence, and when integrated with visual inspection or labeling equipment, they ensure error-free packaging for every batch of pharmaceuticals and compliance with quality standards such as GMP and CE, thereby enhancing product traceability and regulatory compliance. |

| Food | In the food manufacturing industry, fully automatic case packers drastically boost packaging efficiency, ensure neat and hygienic carton packaging, and meet food safety standards. For high-output food production lines (e.g., biscuits, chocolates, coffee sticks), automated case packing delivers consistent throughput and low error rates, providing strong support for handling surges in seasonal orders. |

| Cosmetic | For cosmetics and household goods production lines that require frequent changeovers for multiple product types and small batches, fully automatic case packers leverage servo control systems to enable rapid format changeovers and parameter storage, reducing line changeover time and enhancing production line flexibility and responsiveness. |

| Electronics | For e-commerce fulfillment centers that handle high volumes of small, diverse products, this tuck end box automatic cartoning machine delivers fast, consistent packaging to meet the demands of online retail. It can quickly adapt to a wide range of product sizes and packaging styles, from beauty kits to electronic accessories, while ensuring neat, secure carton sealing that reduces damage during shipping. The machine’s rapid changeover capability supports the frequent SKU switches common in e-commerce, and its reliable performance helps cut down on order processing time, improving delivery speed and customer satisfaction. |

Case

Working Process

| Step | Process |

|---|---|

| 1 | Automatic carton feeding |

| 2 | Carton opening and forming |

| 3 | Product insertion |

| 4 | Tuck end closing |

| 5 | Finished carton output |

Specifications

| Parameter | Value |

|---|---|

| Model | HL-ZC-01 |

| Machine type | Tuck end box automatic cartoning machine |

| Operation mode | Fully automatic |

| Carton type | Tuck end paper box |

| Drive system | Automatic mechanical / servo system |

| Power supply | 220V / 50Hz |

| Application industries | Pharmaceutical, Food, Cosmetic, Daily Chemical |

Production Line Integration

HL-ZC-01 can work independently or be integrated with other packaging equipment.

| Equipment | Function |

|---|---|

| Feeding device | Automatic product feeding |

| Filling machine | Product filling before cartoning |

| Labeling machine | Carton labeling |

| Case packing machine | Secondary packaging |

This allows customers to build a complete automatic packaging production line.

Why Choose HL-ZC-01

| Advantage | Description |

|---|---|

| Stable performance | Designed for continuous operation |

| Packaging quality | Neat carton forming and closing |

| Automation | Reduces manual labor |

| Flexibility | Suitable for various carton sizes |

| Application range | Suitable for multiple industries |

FAQ

Q1: What sizes of cartons are supported?

A: Common-specification cartons are supported, and rapid changeover enables switching between different sizes.

Q2: Can it be integrated with other equipment in the complete production line?

A: It can be seamlessly integrated with packaging equipment such as labeling machines and conveyor lines.

Q3: What about after-sales service?

A: Remote and on-site commissioning as well as training services are provided.

Contact Us

For detailed specifications, pricing, or packaging solutions, please contact us.

We will provide suitable recommendations according to your packaging requirements.

✉️Email: [email protected]

📞WhatsApp:+86 13602308576

| Application Industry | Cosmetic, Electronic Product, Food, Hardware |

|---|---|

| Products | Cartoning Machine |

Reviews

There are no reviews yet.