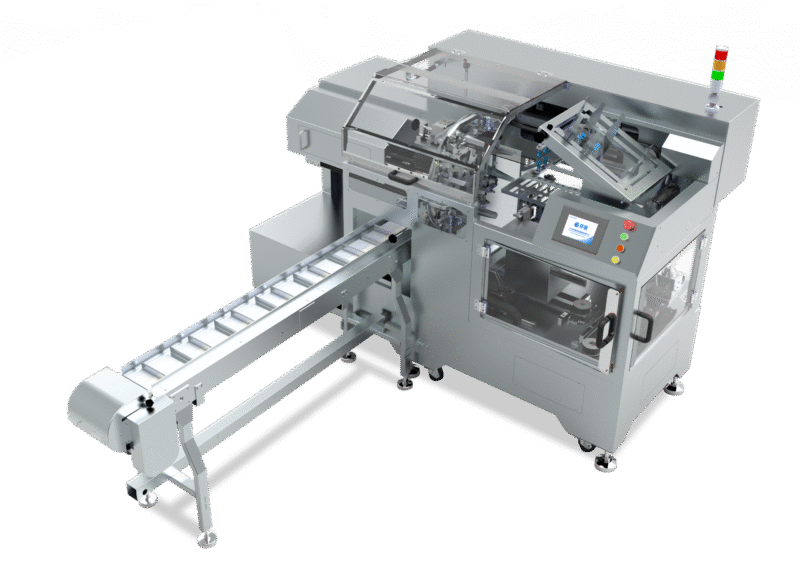

YH-TA21G-35 T-Type High Speed Bagging Machine

The YH-TA21G-35 T-Type High Speed Bagging Machine is a next-gen automated friction-feed bagging solution built for the stationery and printing industries. It combines a high-performance card feeder with on-demand pouch forming, delivering 1,200–3,000 units/hour for textbooks, postcards, red envelopes, and flat office supplies. Using roll film for custom-sized bags, it cuts material costs while ensuring scratch-free handling, easy operation, and 24/7 reliability—ideal for large-scale, retail-ready packaging.

Product Description

The YH-TA21G-35 T-Type High Speed Bagging Machine represents the next generation of automated friction-feed bagging technology. This T-type high-speed system is specifically tailored for the stationery and printing industries, where precision and speed are paramount. By integrating a high-performance card feeder with an on-demand pouch-forming unit, it eliminates the need for expensive pre-made bags and manual insertion. Whether you are packaging delicate postcards or thick textbooks, this machine delivers a retail-ready finish at a fraction of the traditional labor cost.

Product Features

- Rapid Throughput Capacity: Engineered for high-demand environments, achieving a consistent output of 1,200 to 3,000 units per hour, making it a powerhouse for large-scale fulfillment.

- Versatile Friction Feeding: Equipped with a sophisticated automatic card issuing mechanism that handles a wide variety of flat materials with zero surface scratching.

- Cost-Efficient Film Conversion: Utilizes economical roll film to create custom-sized bags on the fly, significantly reducing material overhead compared to pre-pouched solutions.

- User-Centric Engineering: The scientific and simplified design ensures that the system is easy to learn for new operators, with minimal training required.

- Stability at Scale: Built on a high-reliability main support frame, the machine maintains perfect sealing alignment even during continuous 24/7 operation.

Application

The YH-TA21G-35 is the premier solution for flat-profile product packaging:

- Publishing & Education: Ideal for textbooks, picture albums, notebooks, and educational workbooks.

- Stationery & Gifts: The ultimate system for red envelopes, greeting cards, postcards, and decorative stickers.

- Office Supplies: Efficiently bags file folders, envelope sets, A4 paper stacks, and certificates of honor.

- Specialty Paper: Suitable for thermal paper rolls, instruction manuals, and promotional brochures.

Optional Functions (Customized for Your Needs)

- Dynamic Coding Integration: Seamlessly add an online inkjet printer or TTO system for real-time printing of barcodes and expiration dates.

- Precision Labeling: Integrate an automatic labeling head to apply brand stickers or security seals during the bagging process.

- Multi-Item Collating: Customize the intake with multiple feeder stations to create multi-pack sets (e.g., a notebook with an instruction manual).

- Smart Waste Reduction: Advanced sensors ensure the “no product – no bag” feature is active, preventing film waste during feeding gaps.

Working Process

- Material Unwinding: The roll film feeding mechanism provides a continuous supply of packaging material.

- Automated Dispensing: The friction-feed card issuer drops the product onto the conveyor with precision timing.

- Synchronized Transport: The product conveying mechanism moves the item into the forming area.

- Enveloping & Filling: The push-bag filling system slides the product into the newly formed film sleeve.

- Clean-Cut Sealing: The automatic sealing mechanism closes the bag, while the discharging mechanism moves the finished product to the collection bin.

Technical Specifications

| Specification | Detail | Specification | Detail |

|---|---|---|---|

| Power Supply | 220V / 3.5kW | Net Weight | 1460kg |

| Air Pressure | 0.5-0.7Mpa | Air Flow | 300-500L/min |

| Machine Dimensions | 3950 * 2825 * 1505mm | Production Rate | 20-50 ppm |

| Product Compatibility | L(145-300) W(100-210) H(5-20)mm | Bagging Range | L(200-370) W(120-230)mm |

Video

Click 👉:More Case Videos

FAQ

Q1: Can this machine handle very thin products like a single postcard?

A: Absolutely. The automatic card issuing machine is designed for precision, allowing it to feed and bag thin items like postcards and red envelopes without doubles or jams.

Q2: Is the machine easy to adjust for different product sizes?

A: Yes, the structure is easy and fast to adjust. Changeovers between different notebook sizes or folders can be completed quickly, maximizing your production flexibility.

Q3: What are the benefits of the T-Type configuration?

A: The T-Type design allows for a more ergonomic feeding process and better integration with secondary card issuers, making it the most efficient layout for flat-product bagging.

Contact Us

For detailed specifications, pricing, or packaging solutions, please contact us.

We will provide suitable recommendations according to your packaging requirements.

✉️Email: [email protected]

📞WhatsApp:+86

Reviews

There are no reviews yet.