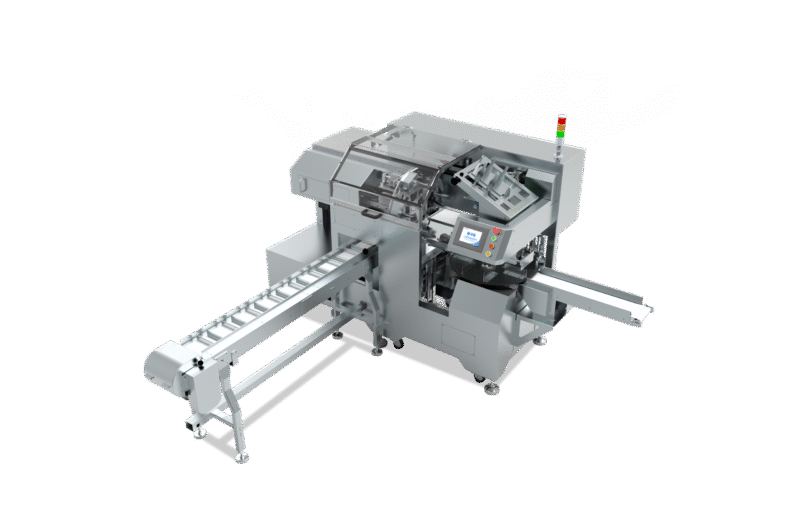

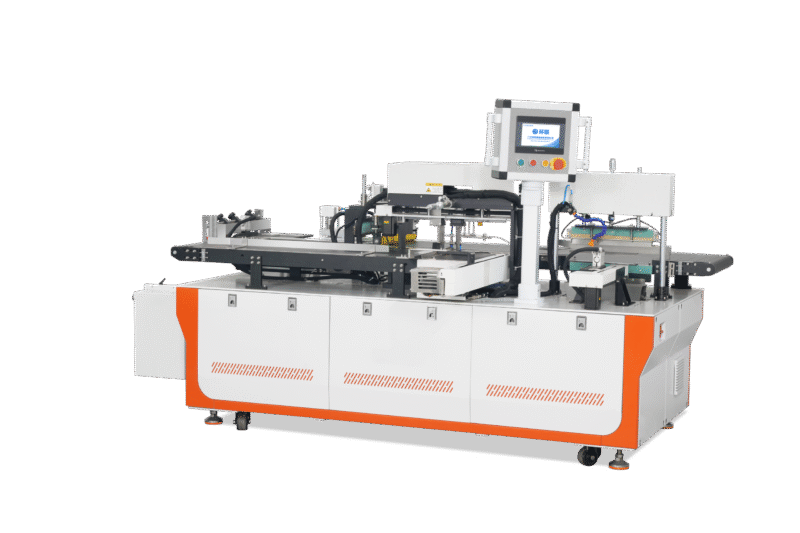

YH-MA51K Organ Bag High Speed Bagging Machine(2)

The YH-MA51K High Speed Organ Bagging Machine is a professional automated device for gusseted bags, boasting high-precision servo control, a specialized rotating mechanism and full auto workflow from bag retrieval to sealing, with a speed of 20-50 pcs/min, stable structure and easy operation via touch screen HMI. It is widely used in daily necessities, food, medical, electronics and other industries for packaging thick or stand-up products, compatible with multiple film materials and support customized functions like TTO coding and custom bag sizes. Its core advantage lies in perfect non-deformable processing of organ bags, even for bulky items, and customized packaging solutions are available upon contact via the provided email and WhatsApp.

Product Description

The YH-MA51K Organ Bag High Speed Bagging Machine is a high-performance automated system designed specifically for the challenges of gusseted (organ-style) bag packaging. Unlike standard flat-bagging machines, the MA51K features a unique 3D-opening technology that perfectly expands the side folds of organ bags, allowing for the smooth insertion of thick or boxed products. This system is the ultimate upgrade for manufacturers in the tissue, textile, and food industries who require a premium, stand-up shelf presence for their products. By combining high-speed servo precision with a compact footprint, it delivers retail-ready packaging with unmatched consistency.

Product Features

- 3D Gusset Expansion Technology: Specialized bag-holding and rotating mechanisms ensure that organ bags are fully and evenly opened, preventing product snags and ensuring a clean, professional look.

- Intelligent Servo Synchronization: Utilizing a state-of-the-art servo control system, the machine achieves seamless coordination between material pushing and bag clamping, minimizing downtime and mechanical wear.

- High-Load Material Handling: Engineered to handle substantial products—from heavy bath towels to multi-pack facial tissues—with a reinforced pushing mechanism that maintains speed under load.

- Flexible Material Compatibility: Expertly processes a wide range of high-barrier films including CPP, PE, and Aluminum foil, ensuring product freshness and protection.

- Streamlined HMI Interface: The intuitive touch-screen interface allows for rapid recipe switching, enabling operators to change product sizes in minutes rather than hours.

Application

The YH-MA51K is the specialized choice for voluminous and stand-up packaging:

- Home & Textiles: Ideal for towels, pillowcases, and microfiber cloths that require thick, gusseted bags.

- Personal Care: The standard for sanitary napkins, baby diapers (small packs), and facial tissue bundles.

- Food & Confectionery: Perfect for boxed cookies, bread loaves, and products in bottom-box trays that need a stable base.

- Industrial & Medical: Suitable for first-aid kits, boxed masks, and large electronic component kits.

Optional Functions (Customized for Your Needs)

- Integrated Printing Solutions: Add an online coding system to print QR codes, production dates, and batch numbers directly onto the film.

- Automatic In-feed Integration: Can be paired with upstream stacking or folding machines for a fully hands-free production line.

- Gusset Tucking Precision: Optional mechanical tuckers to ensure the side folds are perfectly re-formed before the final seal.

- Static Elimination: For high-speed film handling, an optional ionizing bar can be added to prevent bag sticking and ensure smooth opening.

Working Process

- Bag Retrieval: The automatic bag taking and opening mechanism extracts a pre-made organ bag from the storage unit.

- Positioning: The bag holding and rotating mechanism aligns the bag perfectly for filling.

- Filling: The product conveying and material pushing mechanism accurately inserts the product into the opened bag.

- Clamping & Sealing: The bag-open clamping mechanism secures the top while the automatic sealing mechanism creates a professional bond.

- Discharge: The product discharging mechanism transfers the finished organ bag to the next stage of the logistics chain.

Technical Specifications

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Input Voltage | AC220V / 8.0kW | Equipment Weight | 750kg |

| Operating Pressure | 0.5-0.7Mpa | Air Consumption | 600L/min |

| Equipment Size | 2940 * 2910 * 1425mm | Production Speed | 20-50 pcs/min |

| Applicable Bag Size | L100-300 / W70-150 / H40-90mm | Applicable Material | CPP, PT, PE, CPP aluminized/aluminum film |

Video

Click 👉:More Case Videos

FAQ

Q1: Why choose the YH-MA51K over a standard flat bagging machine?

A: Standard machines often struggle to open the side folds of organ bags. The YH-MA51K is built with a specific rotating and expanding mechanism that ensures the bag is fully opened in 3D, allowing for thicker products to fit perfectly.

Q2: How does the machine ensure a strong seal on thick gusseted bags?

A: The automatic sealing mechanism is adjustable for temperature and dwell time, ensuring that even the four-layer thickness of the gusseted sides is sealed as securely as the two-layer center.

Q3: Is this machine suitable for food-grade environments?

A: Yes, the design is clean and accessible, making it suitable for food packaging environments. It works excellently with CPP and Aluminum films commonly used in the food industry.

Q4: Can it be integrated into an existing conveyor line?

A: Absolutely. The product conveying mechanism is designed for easy synchronization with upstream equipment, making it a “plug-and-play” addition to most automated lines.

Contact Us

For detailed specifications, pricing, or packaging solutions, please contact us.

We will provide suitable recommendations according to your packaging requirements.

✉️Email: [email protected]

📞WhatsApp:+86

| Products | Bagging Machine |

|---|---|

| Application Industry | Electronic Product, Food, Hardware, Toy |

Reviews

There are no reviews yet.