Bagging Machine Picking Up Bags but Not Letting Go?

Alyssa/ December 2, 2025 Return

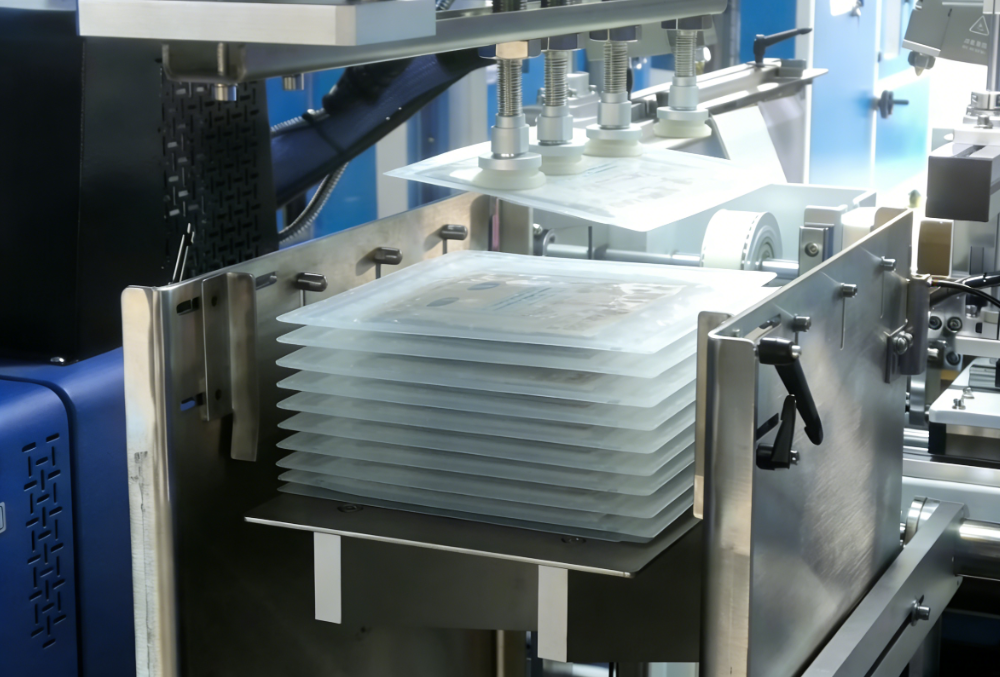

The Panic Moment: When the Machine Picks Up the Bag but Refuses to Release It

That Horrifying “Sheet Mask Stuck to the Suction Cup” Moment

Everything looks normal at first.

The suction head lifts the bag smoothly…

And then—

it stays stuck, refusing to drop like it’s glued to the cup.

The suction head retracts → the bag follows.

The next cycle starts → the bag is still attached.

Your entire line freezes.

You can only think:

“Please… JUST… LET… IT… GO!”

How One Stuck Bag Destroys the Entire Workflow

When the bag doesn’t release:

- The clamps miss their timing

- The machine repeats cycles

- Rhythm collapses

- Backlogs appear instantly

- Production comes to a halt

A tiny failure turns into a production nightmare.

The Real Reason: Not Suction Power, but a Slow Suction Head Reset

Even a 0.1s Reset Delay Can Cause Vacuum Lock

If the suction head resets too slowly, residual vacuum remains.

Combined with static electricity or thin bag materials,

the bag clings like glue.

Why the Suction Head Resets Slowly (Fully Explained)

- Return spring fatigue after thousands of cycles

- Dust buildup causing friction on the slider

- Airflow delay inside the suction system

- Aging suction cup increasing surface adhesion

One tiny slowdown → full system cascade failure.

What Happens If You Ignore the Slow Reset?

The Downward Spiral That Gets Worse Every Hour

You’ll see:

- More sticking

- More mis-timed releases

- More repeated motions

- Random shutdowns

- Heavy stress on operators

- A constantly collapsing line

This problem never fixes itself.

Worst Case: Line Shutdown and Component Damage

- Suction head wear accelerates

- Motor load spikes

- Airflow system strains

- Replacement becomes necessary

Small issue → big consequences.

The Fix Is Shockingly Simple: Maintain the Reset System

Three Quick Actions That Restore Everything

- Check spring tension

- Clean + lubricate the slider

- Replace the suction cup or spring if aging

Maintenance takes minutes, results last weeks.

Your Machine Will Feel “New” Again

After proper reset maintenance:

- Bags drop instantly

- Movement becomes smooth

- Cycle timing stabilizes

- Production recovers immediately

UBL’s suction head system is durable,

but every high-frequency mechanism needs maintenance.

Conclusion: When Bags Don’t Drop, Ask This One Question

It’s Not the Bag, Not the Film, Not the Program—It’s the Reset

If your machine:

- Picks up bags

- But won’t release them

- Repeats actions

- Breaks rhythm

- Randomly stops

90% of the time, the reset system is the real culprit.

Tell Me Your Bag Material—I’ll Predict Your Maintenance Cycle

Different materials = different adhesion

Different thickness = different stress levels

Different workloads = different replacement cycles

| Issue | Cause | Impact on Production | Recommended Maintenance | Related Equipment (UBL) |

|---|---|---|---|---|

| Suction cup not releasing bags | Slow suction head reset | Machine cycle repeats, line slowdown | Clean slider, lubricate, check spring | UBL Automatic Bagging Machine |

| Bag sticking to suction head | Residual vacuum + static electricity | Bags hang on suction head, jam risk | Reduce vacuum delay, replace suction cup | UBL Vacuum Suction System |

| Delayed suction head movement | Return spring fatigue | Timing errors, incomplete actions | Replace return spring | UBL Suction Head Assembly |

| Suction cup aging | Rubber hardening after high-frequency cycles | Increased adhesion, stuck bags | Replace suction cup | UBL Suction Cup Module |

| Airflow release too slow | Air circuitry blockage or dust buildup | Vacuum lock, bag not dropping | Clean air path, adjust airflow | UBL Air Circuit Control System |