Carton Erector Sensors Misreading? Dust Is More Dangerous Than a Real Failure!

Alyssa/ November 19, 2025 Return

Have you ever seen your carton erector suddenly start giving one false alarm after another? Sometimes it thinks a carton isn’t there, sometimes it thinks one is when it’s not, and the whole machine keeps stopping and starting. Most operators assume the sensor is broken, but the real problem is usually much simpler — dust and paper debris blocking the sensor’s “eyes.”

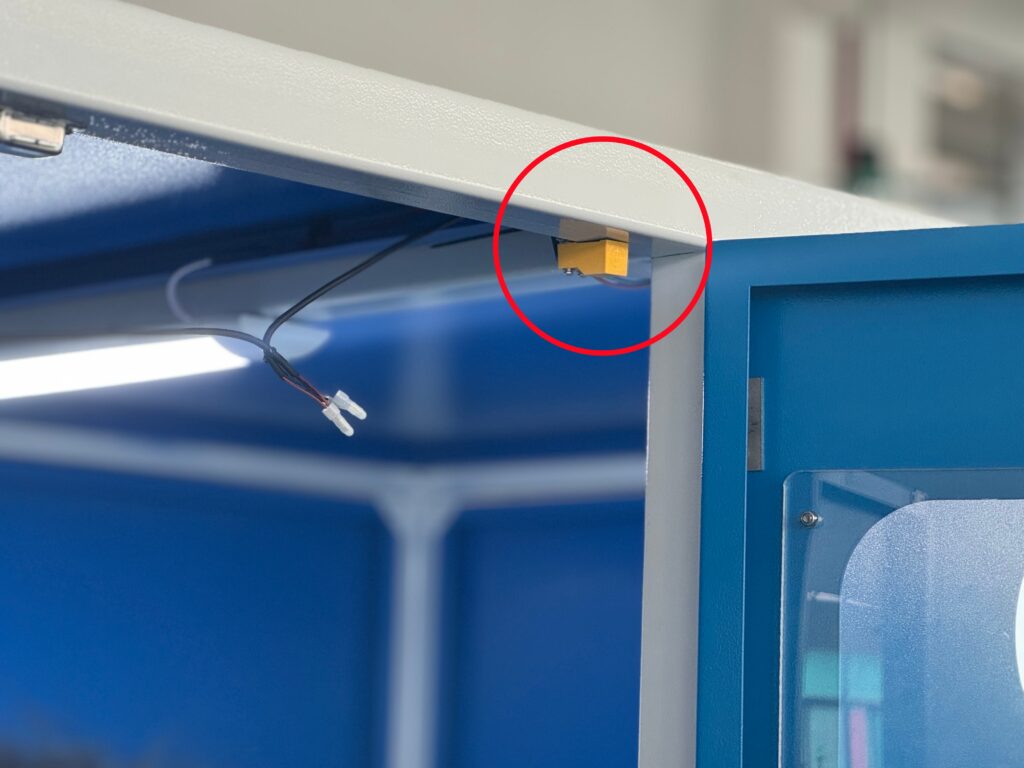

In industries like food packaging, baby products, and light industrial goods, carton erectors work at high speed all day. During this process, cartons constantly rub against guides and suction cups, creating tiny paper particles. These particles, along with normal workshop dust, quickly settle on the surface of the photoelectric sensors. Even a thin layer of dust can cause misreads, timing errors, or unstable operation. UBL’s carton erectors use highly sensitive sensors, but the more sensitive the sensor, the easier it is for dust to interfere.

The fix is surprisingly simple. Before each shift or at machine startup, wipe the sensor gently with a clean, lint-free cloth. Removing even a small amount of dust often restores accurate detection instantly. If your workshop produces a lot of paper debris, consider adding UBL’s mini dust covers to the sensor area. They protect the sensor without reducing detection distance, and many factories report that their machines run much more smoothly with just this small addition.

Does your carton erector trigger false alarms often? Tell me which industry you’re in, and I can help identify which sensor is most prone to dust issues in your environment.