From Raw Materials to Finished Products: How Does a Fully Automatic Packaging Line Work?

Alyssa/October 5,2025

A fully automatic packaging line is like a “smart factory within a factory”—it transforms scattered raw materials (cartons, products, packaging films) into neatly stacked finished goods through 5 consecutive links, with zero manual intervention in core processes. Huanlian Packaging Group, as a leader in intelligent packaging solutions, has built modular automatic lines for industries such as food, auto parts, and building materials. Taking its HL-FULL600 fully automatic packaging line (applied in Hebei Jinxi Iron and Steel and Tangsteel Legang) as an example, let’s decode the whole workflow from material inlet to finished product outlet.

Core Logic: The “Central Brain” That Controls Everything

Before understanding the workflow, we must first clarify the core of Huanlian’s automatic line—the HL-CCS200 central control system. This system integrates German Siemens PCC servo control and American Allen-Bradley PLC, which can:

- Synchronize WMS order data (e.g., “Product: φ20mm Steel Bar, Qty: 50pcs/Box, Target Output: 300 Boxes/Hour”);

- Automatically adjust parameters of 6+ devices in the line (response time < 0.3s);

- Real-time monitor 12 key indicators (e.g., sealing temperature, conveyor speed) and trigger alarms for abnormalities (e.g., “Low Film Level → Pause Feeding”);

- Generate production reports (e.g., “Daily Output: 7,200 Boxes, Defect Rate: 0.1%”).

It is this “brain” that ensures the entire line operates like a precise clockwork.

Step 1: Raw Material Preprocessing – Automated Supply Without Manual Handling

Raw materials include two categories: packaging materials (cartons, woven bags, films) and products to be packaged (steel bars, auto parts). Huanlian’s equipment completes preprocessing and supply in parallel:

1. Packaging Material Supply System

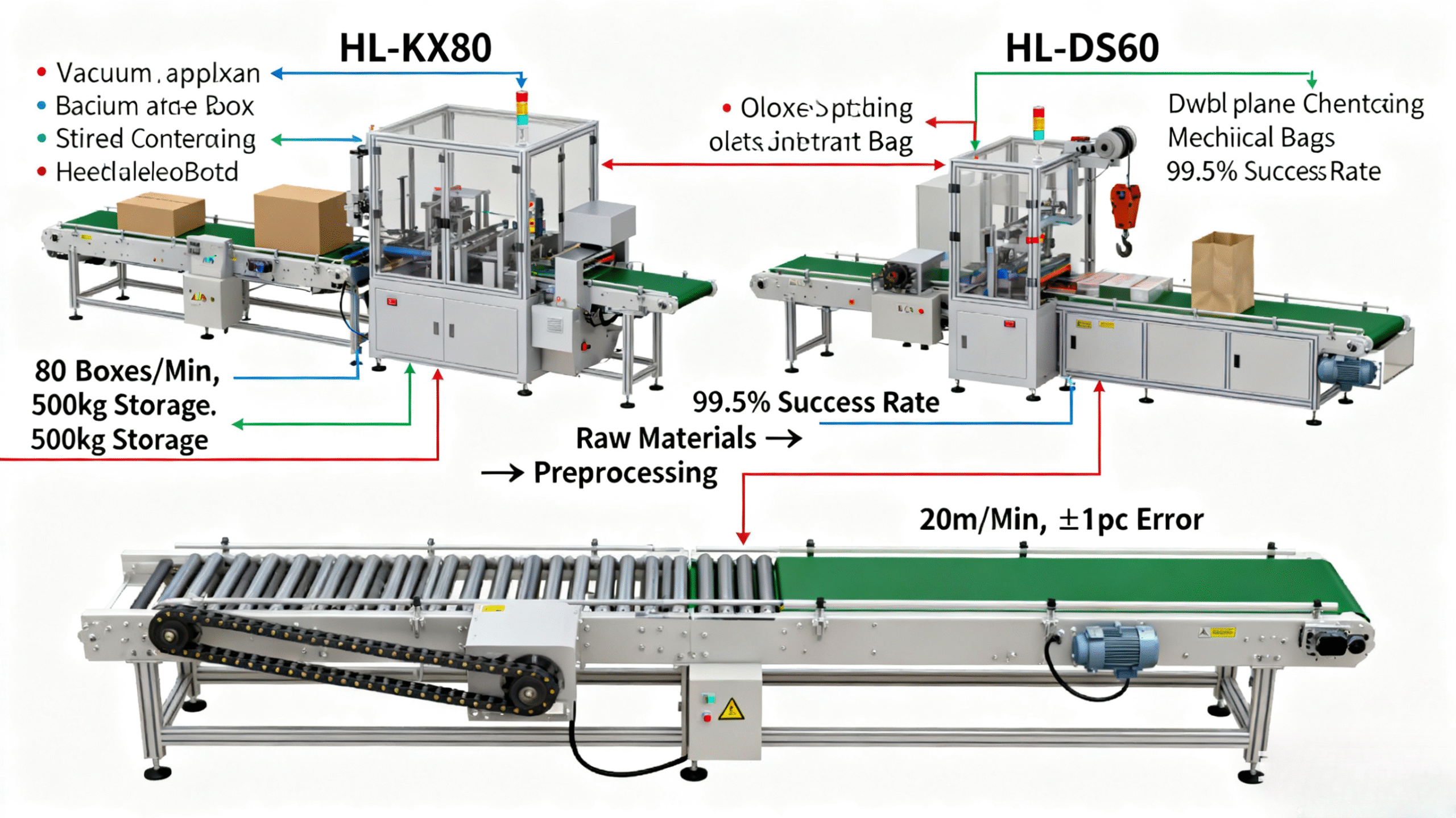

- HL-KX80 Automatic Box Erector: Stores 500+ flat cartons in the material rack. The vacuum sucker automatically takes out the cartons, folds them along creases, and seals the bottom with hot melt adhesive (adhesion strength ≥ 50N/cm). The speed reaches 80 boxes/min, which is 4 times that of manual work.

- HL-DS60 Automatic Bag Feeder: Adopts double-disk switching design (each disk holds 200 woven bags/paper bags) . The photoelectric sensor detects empty bags, and the mechanical claw takes bags and opens them (success rate ≥ 99.5%). It is especially suitable for powder/granular materials (e.g., fertilizer, feed) packaging.

- HL-FM40 Film Unwinding Frame: Equipped with tension control device (0.5-5N adjustable) to ensure the packaging film is smooth and wrinkle-free during unwinding.

2. Product Feeding Conveyor

The chain conveyor (load-bearing ≥ 500kg/m) connects the upstream production line. The infrared sensor counts the products (error ± 1pc/100pcs) and adjusts the conveying speed (0-20m/min) according to the packaging rhythm. For heavy products like steel bars, the anti-skid roller design is adopted to avoid slipping .

Step 2: Precision Filling – Match Products with Packaging Exactly

This link is the “core operation” of packaging. Huanlian’s equipment adapts to different product types with targeted solutions:

1. For Solid Products (Steel Bars, Auto Parts)

- HL-ZD100 Intelligent Carton Filler: Equipped with 6-axis robotic arm and 3D visual recognition system. It grabs 50pcs of φ20mm steel bars at a time, aligns them with the carton opening (positioning error ± 0.5mm), and places them smoothly. The grabbing speed is 12 times/min, which solves the problem of manual carrying injury.

2. For Powder/Granular Products (Fertilizer, Flour)

- HL-CW50 Automatic Weighing & Filling Machine: First, the electronic scale weighs the material (accuracy ± 2g) according to the set value (e.g., 25kg/bag) . Then, the screw conveyor sends the material into the pre-opened woven bag, and the pressure sensor detects the filling level to avoid overflow.

3. Key Technology: Dual Inspection Mechanism

After filling, the laser sensor detects two indicators:

- “Empty Space Rate”: For cartons, it is required to be ≤ 5% (avoid material shaking and damage);

- “Filling Accuracy”: For bags, the deviation is required to be ≤ ± 0.3% (comply with national metrology standards).

Unqualified products are automatically pushed to the rejection channel.

Step 3: Sealing & Labeling – Aesthetic and Anti-Counterfeiting in One

After filling, the semi-finished products enter the sealing and labeling link, which is the “finishing” of packaging:

1. Sealing: Adapt to Different Packaging Materials

- HL-FS70 Hot Melt Sealing Machine: For cartons, the temperature (160-220℃ adjustable) is automatically matched according to the carton thickness. The pressure roller compresses the seal, and the bonding rate is 100% (no degumming in -20℃ low temperature environment).

- HL-FB50 Sewing & Heat-Sealing Machine: For woven bags, it first folds the bag mouth (fold width 2-5cm adjustable) and then sews it with polyester thread (sewing density 8-12 stitches/inch). For paper bags, it uses heat-sealing technology (sealing strength ≥ 30N/15mm) .

2. Labeling: Full Information Traceability

- HL-LB60 Automatic Labeling Machine: Prints 3 types of information in real time through thermal transfer printing:

- Basic information: “Product Model: HL138-1, Production Date: 2025-XX-XX”;

- Traceability code: Unique QR code (scannable to check raw material batch, production operator);

- Anti-counterfeiting mark: Fluorescent watermark (visible under UV light).

The labeling position error is ≤ ± 1mm, and the adhesion is firm (no falling off after 100km vibration test).

Step 4: Post-Packaging Treatment – Stabilize and Protect Finished Products

This link solves the problem of “easy damage during transportation” and prepares for stacking:

1. HL-CZ30 Carton Shaping Machine

For cartons with irregular shapes after filling, the pressing plate (pressure 10-30N adjustable) gently shapes them to ensure the cartons are flat and easy to stack. The shaping speed is synchronized with the conveyor line (up to 60 boxes/min).

2. HL-RM50 Wrapping Machine

For palletized products, the machine wraps the stretch film around the finished product (number of layers 2-6 adjustable). The tension control system (1-5N) adjusts the tightness according to the product weight—light products (e.g., plastic parts) use low tension (1-2N) to avoid deformation, while heavy products (e.g., steel bars) use high tension (4-5N) to prevent scattering .

Step 5: Intelligent Palletizing – Stacking Like Building Blocks Automatically

The final step is to stack the finished products into neat pallets for storage and transportation:

HL-RS20 Robotic Palletizer

Equipped with 6-axis robotic arm (maximum load 150kg) and visual positioning system, it can stack according to 3 preset modes:

- “Block Type”: For cartons (e.g., 4×5×3 arrangement, stack height ≤ 2.2m);

- “Honeycomb Type”: For woven bags (avoid pressure damage to powder materials);

- “Custom Type”: Adapt to special-shaped products (e.g., auto parts).

The stacking speed reaches 120 boxes/bags per hour, and the deviation of stack height is ≤ ± 3mm. After stacking, the pallet conveyor sends the pallets to the finished product warehouse, and the system automatically updates the WMS inventory (“HL138-1 Product: +7,200 Boxes”).

Data Verification: Why Choose Huanlian’s Automatic Line?

Tangsteel Legang installed 2 Huanlian HL-FULL600 lines, and the data after 6 months of operation showed :

- Efficiency: Manual line output was 120 boxes/hour, while automatic line reaches 300 boxes/hour (+150%);

- Cost: Labor from 12 people/line to 2 people/line (1 operator + 1 maintenance), monthly labor cost saved $36,000;

- Quality: Defect rate from 3.2% to 0.1% (mainly due to automatic inspection);

- Stability: Continuous operation for 720 hours without failure (MTBF ≥ 5,000 hours).

From raw material supply to finished product storage, Huanlian’s fully automatic packaging line realizes the whole process of “data-driven, equipment linkage, and automatic control”. It not only solves the pain points of manual packaging (low efficiency, high error rate, high cost) but also provides traceable and controllable production data for enterprises—this is the core value of intelligent packaging in the new industrial era.

Newsletter Updates

Enter your email address below and subscribe to our newsletter