How One Automatic Cartoning Machine Can Save a Factory $120,000 a Year

Alyssa/ December 18, 2025 Return

The real cost of manual cartoning in modern factories

Many factory owners focus on the price of machines when they think about automation.

What they often miss is the real cost of manual cartoning.

Let’s look at a very common factory situation.

A factory uses five workers only for cartoning.

Each worker costs around two thousand dollars per month after wages, insurance, and overtime.

That means ten thousand dollars every month.

That means one hundred and twenty thousand dollars every year.

This number only covers labor.

It does not include rework caused by poor box alignment.

It does not include buyer complaints about packaging quality.

It does not include production delays when workers change shifts or don’t show up.

It also does not include orders lost because cartoning speed cannot keep up.

Manual cartoning looks cheap only because most factories never calculate the full cost.

Why manual cartoning creates unstable production output

Many factory owners say labor is still affordable in their country.

That may be true.

The real problem is not labor cost.

The real problem is unstable output.

With manual cartoning, production depends on people.

One shift works faster.

Another shift works slower.

One worker is careful.

Another worker is tired.

The same factory can produce very different results on the same day.

When buyers ask if a factory can deliver fifty thousand units every month with the same packaging quality, manual cartoning makes this question hard to answer.

Automatic cartoning machines vs manual labor in real factories

We see this comparison often.

One factory uses several workers for manual cartoning.

Boxes are sometimes crooked.

Speed drops during shift changes.

Another factory uses one operator and an automatic cartoning machine.

The machine runs at a steady speed.

Each box looks the same from the first unit to the last.

After one year, the factory using manual cartoning spends over one hundred and twenty thousand dollars on labor.

The factory using an automatic cartoning machine reduces long-term operating cost and gains stable output.

This gap grows larger every year.

Why buyers care so much about cartoning quality

Buyers do not see how hard factory workers try.

They only see the packaging.

They notice whether the box looks straight.

They notice whether the product sits correctly inside the carton.

They notice whether different shipments look the same.

When packaging quality looks unstable, buyers start to question whether a factory is reliable for long-term cooperation.

Many buyers do not complain.

They simply move their orders to another supplier.

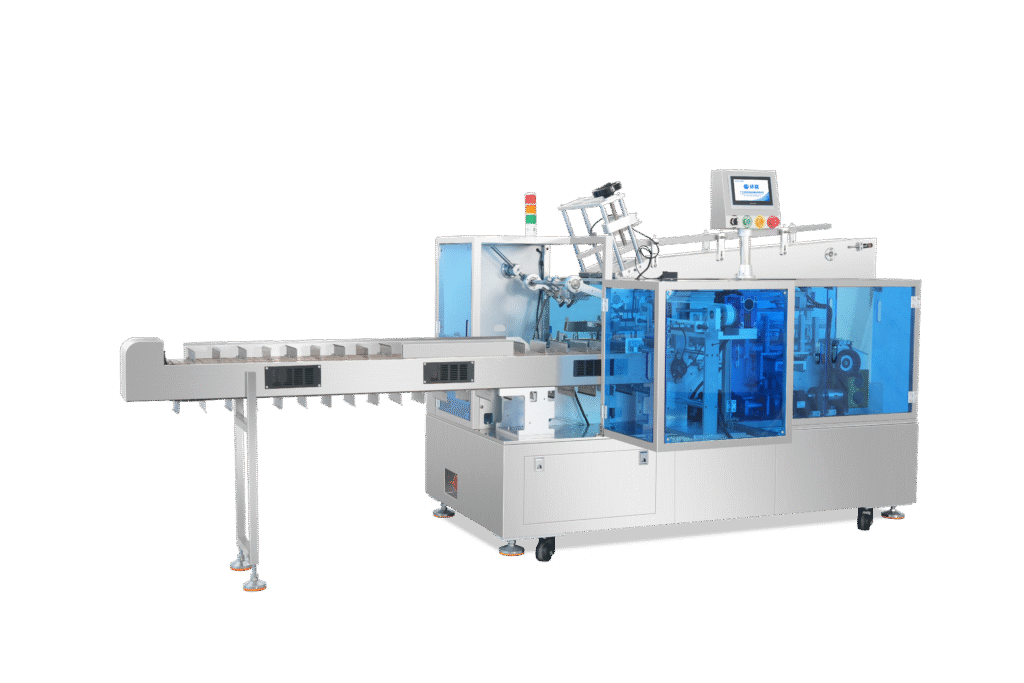

How our automatic cartoning machines solve these problems

These are the exact problems our automatic cartoning machines are designed to solve.

Our focus is not extreme speed.

Our focus is stable production, reduced labor dependence, and consistent packaging quality.

Our cartoning machines automatically open cartons, insert products, close cartons, and detect errors during the process.

In real factory use, this allows one operator to do the work that previously required several workers.

The machine does not get tired.

It does not slow down during night shifts.

It performs the same operation repeatedly with the same accuracy.

As a result, packaging becomes consistent, buyer confidence improves, and factories can plan production with clear numbers instead of guesses.

Automatic cartoning as a long-term factory upgrade

Most factories do not automate everything at once.

They usually start with one automatic cartoning machine.

Later, they connect it to upstream production or downstream packing equipment.

Over time, a simple upgrade becomes a complete packaging line.

Our cartoning machines are designed to support this step-by-step growth.

Factories can improve efficiency without rebuilding their entire production system.

Is an automatic cartoning machine worth it for your factory

The real question today is not whether an automatic cartoning machine is expensive.

The real question is how much manual cartoning is already costing your factory every year.

Once factory owners calculate this clearly, the decision often becomes much easier.

Talk to us about your cartoning needs

Every factory is different.

Product types, carton sizes, and output targets are never the same.

If you want to know whether our automatic cartoning machine fits your factory, tell us what product you pack and how many cartons you produce per day.

Leave a comment or send us a message.

We are happy to look at real factory data and share practical suggestions.

No pressure.

Just honest manufacturing logic.

| Topic | Keywords | Machines | Insight | Recommended CTA |

|---|---|---|---|---|

| Green Efficiency Packaging | green packaging, packaging efficiency, waste reduction | HL-Z15 Cartoning Machine, Folding Machine | Automation helps factories reduce carton waste and control material cost while improving packaging consistency. | Upgrade packaging lines to reduce waste and improve long-term efficiency. |

| Material Waste Control | packaging waste, sealing waste, carton waste | Bagging Machine, Folding Box Machine | Manual packaging lines increase material waste under rising paper and film costs. | Adopt automated packaging systems to stabilize material usage. |

| Packaging Precision | consistent packaging, high-speed packaging, packaging precision | UBL Packaging Automation System | Precision-controlled packaging reduces rejects and rework caused by misaligned cartons. | Switch to automated cartoning systems for consistent packaging output. |

| Labor Cost Reduction | labor cost reduction, factory automation, packaging labor | Automatic Cartoning Machine | Labor-dependent cartoning creates unstable output and rising long-term operating costs. | Replace manual cartoning with automation to stabilize labor cost. |

| Scalable Packaging Lines | scalable packaging line, packaging line upgrade, factory expansion | Automatic Cartoning Machine, End-of-Line System | Factories need packaging systems that can grow with production volume without rebuilding lines. | Start with a cartoning machine and expand step by step. |