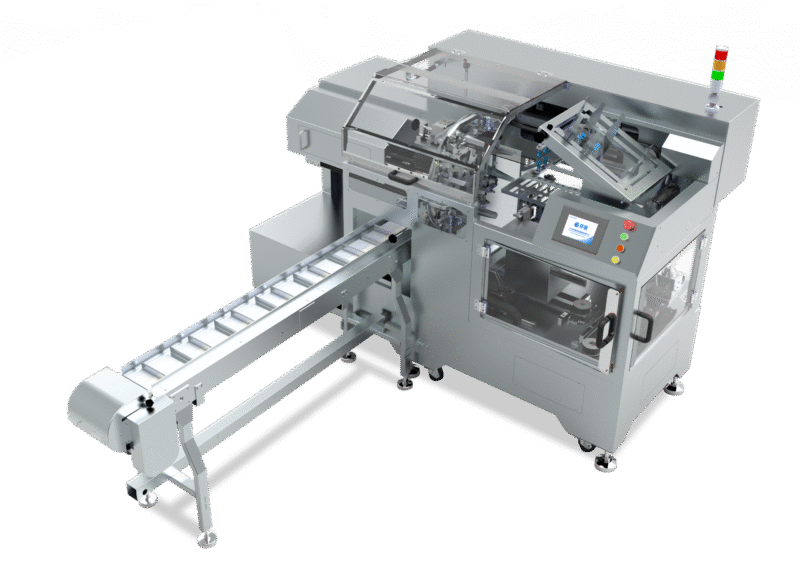

YH-ZA11C-48 Four Corner Cutting Shrink Wrapping Machine

The YH-ZA11C-48 Four Corner Cutting Shrink Wrapping Machine delivers a tight, clean four-corner cut finish for boxed products, integrating film feeding, bag making, bagging and corner cutting for premium retail packaging.

Product Description

The YH-ZA11C-48 Four Corner Cutting Shrink Wrapping Machine represents the pinnacle of aesthetic packaging technology. Unlike standard bagging machines, this model is specifically designed to provide a tight, clean, and professional “four-corner cut” finish for boxed products. It integrates film feeding, bag making, bagging, and corner cutting into one automated unit, making it the perfect choice for high-end retail products that require premium shelf appeal.

Product Features

- Precision Mechanism: The system includes an automatic film feeding mechanism, automatic film drawing, bag-making, bagging, sealing, and a specialized four-corner cutting mechanism for a perfect fit.

- Waste Management: Equipped with an integrated waste disposal mechanism to keep the production area clean and efficient.

- Optimized Performance: Designed to meet high-efficiency requirements of 350-600 pcs/h, balancing speed with delicate handling.

- Reliable & Simple: The scientific structure ensures high reliability and is engineered to be easy to adjust, maintain, and learn.

Application

The YH-ZA11C-48 is widely used in life, study, electronics, and medical fields for box bagging packaging:

- Gift & Luxury Items: Perfect for Gift Box Bagging and Tea Box Packaging.

- Electronics: Ideal for Electronic Product Packaging Boxes (e.g., headphones, small gadgets).

- Cosmetics & Personal Care: The go-to solution for Cosmetic Packaging Boxes, skincare sets, and perfume boxes.

- Apparel & Textiles: Suitable for Shoe Boxes, Towel Boxes, and Underwear/Pantyhose Box Bagging.

- Medical Supplies: Professional packaging for Medicine Packaging Boxes.

Working Process

- Film Feeding: The machine automatically draws film from the roll.

- Bag Making: The film is formed into a custom-sized pouch around the product.

- Four Corner Cutting: Precision blades trim the corners for a flush fit.

- Sealing: The edges are sealed, and waste is automatically collected.

- Discharge: The finished box is conveyed to the next stage (usually a shrink tunnel).

Technical Specifications

| Item | Specification | Item | Specification |

|---|---|---|---|

| Input Voltage | AC 220V | Equipment Weight | 1500kg |

| Power | 10kW | Equipment Size (LWH) | 2600 * 1420 * 1810mm |

| Operating Air Pressure | 0.5-0.7Mpa | Air Consumption | 600-800L/min |

| Applicable Product Size | L100-300 / W50-150 / H30-100mm | Applicable Bag Size | L+2H+80 ≤ 450mm; W+H+30 ≤ 300mm |

Video

Click 👉:More Case Videos

FAQ

Q1: What is “Four Corner Cutting” and why is it important?

A: Four-corner cutting removes the excess film at the corners of a box before or during the sealing process. This results in a much cleaner, “square” finish compared to standard pillow-style bagging, which is essential for high-end retail gift box packaging.

Q2: Can the YH-ZA11C-48 handle different box sizes?

A: Yes. It is adjustable for products within the range of 100-300mm in length and 50-150mm in width. The automatic film drawing mechanism ensures the film is tensioned correctly for various heights (30-100mm).

Q3: Does this machine include a shrink tunnel?

A: This unit focuses on the bagging and precision corner cutting. For a complete finish, it is typically paired with a shrink tunnel to tighten the film around the box after the four-corner cut is made.

Contact Us

For detailed specifications, pricing, or packaging solutions, please contact us.

We will provide suitable recommendations according to your packaging requirements.

✉️Email: [email protected]

📞WhatsApp:+86

| Application Industry | Electronic Product, Medical Pharmaceutical |

|---|---|

| Products | Bagging Machine |

Reviews

There are no reviews yet.