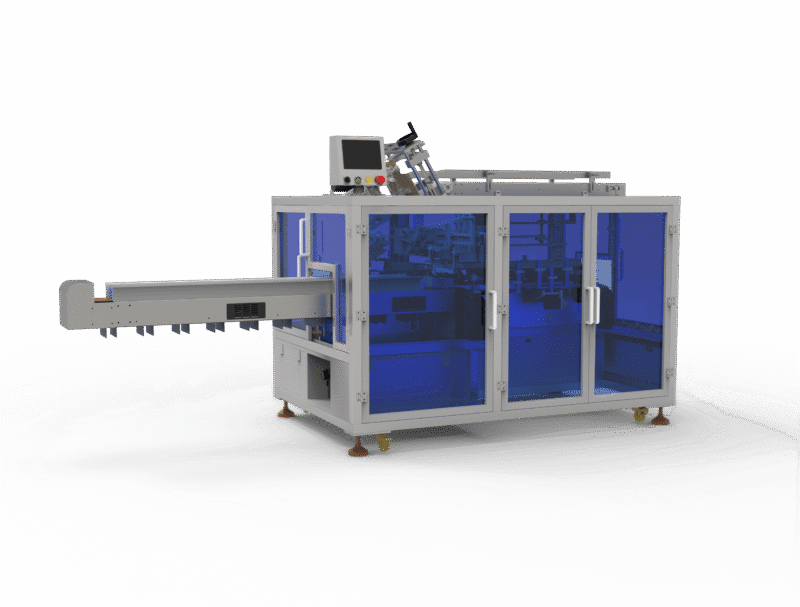

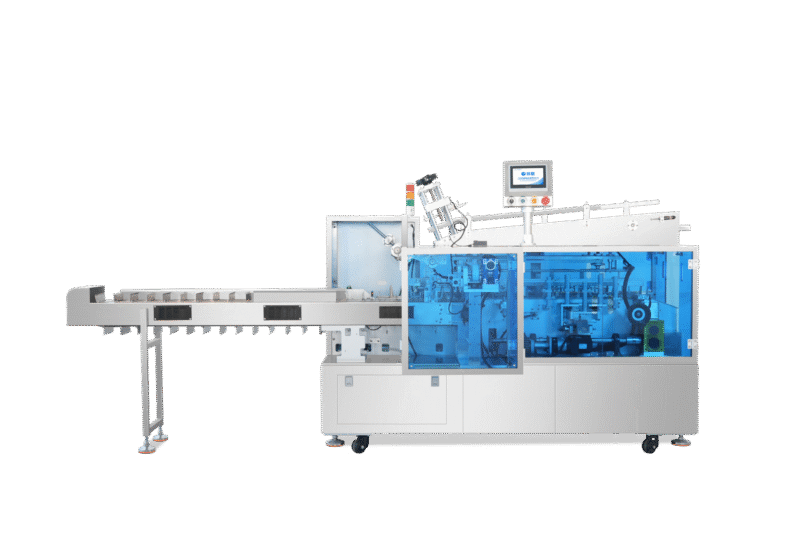

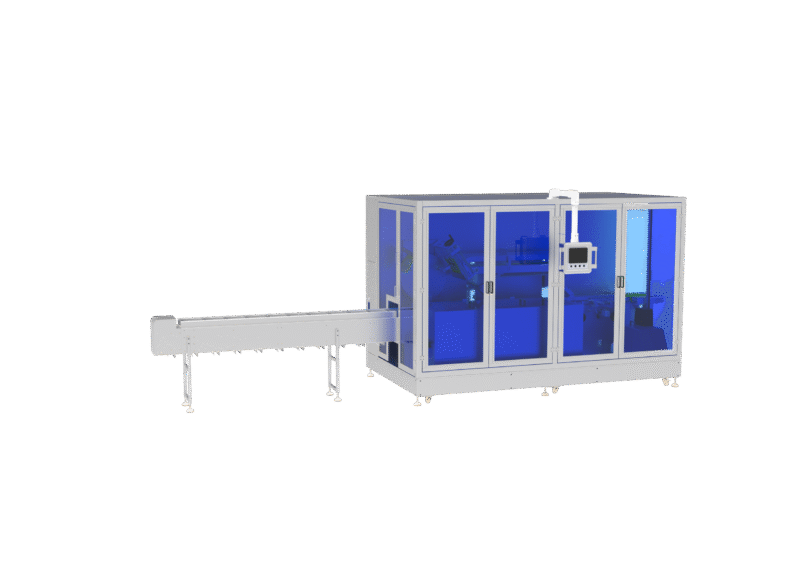

HL-ZC-G1 Servo Tuck End Box Cartoning Machine

The HL-ZC-G1 Servo Tuck End Box Cartoning Machine is a high-speed, servo-driven automatic cartoning solution designed for modern food, pharmaceutical, cosmetic, and electronics packaging lines.

Built for demanding production environments, this servo tuck end box cartoning machine delivers stable output from 3,000 to 4,800 cartons per hour, combining precision carton forming, accurate product insertion, and reliable tuck-end closing in a fully automated workflow.

With advanced servo control, bus communication architecture, and fast changeover design, the HL-ZC-G1 is ideal for manufacturers seeking high throughput, consistent quality, and flexible multi-size packaging within a single cartoning system.

Product Description

As a professional Packaging Machinery Manufacturer, our HL-ZC-G1 Servo Tuck End Box Cartoning Machine is a core component of Intelligent Packaging Automation Solutions—engineered for modern high-throughput packaging lines (food, pharmaceutical, cosmetic, electronics).

This automatic cartoning machine integrates bus control & absolute servo positioning, delivering stable output (3,000–4,800 cartons/hour) with full automation: from carton forming to product insertion, tuck-end sealing, and finished output. It’s built to balance speed, precision, and flexibility for multi-SKU production.

Common pain points in industrial packaging lines, solved by the HL-ZC-G1:

- Conventional carton folding machine (relevant to carton processing) can’t meet 3,000+ pcs/h speed for food/FMCG lines

- Generic cartoners cause positioning errors in pharmaceutical packaging at high speeds

- Long changeover times for multi-size cartons in cosmetic production delay output

- Unstable operation during 8+ hour continuous runs disrupts line efficiency

Product Features

| Feature | Description |

|---|---|

| Control system | Full servo motor control |

| Operation | Fully automatic |

| Packaging process | Carton feeding, box opening, product insertion, tuck end closing |

| Running status | Stable and continuous operation |

| Adjustment | Easy adjustment for different carton sizes |

| Integration | Suitable for automatic packaging lines |

Application

This servo tuck end box cartoning machine is widely used in the following industries:

| Industry | Application |

|---|---|

| Pharmaceutical | Medicine boxes, healthcare products |

| Food | Food cartons, nutraceutical packaging |

| Cosmetic | Cosmetic and personal care boxes |

| Electronics | Small electronic product cartons |

| Daily chemical | Household product packaging |

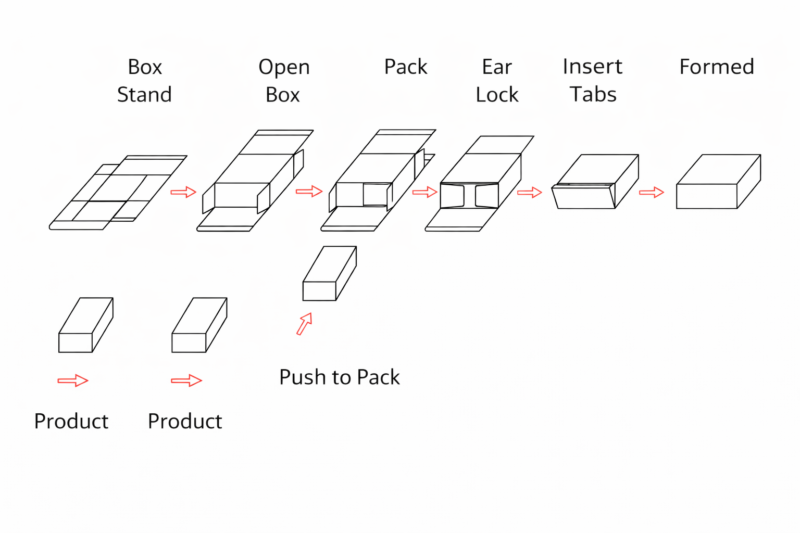

Working Process

| Step | Process Description |

|---|---|

| 1 | Automatic carton feeding |

| 2 | Carton opening and forming |

| 3 | Product insertion |

| 4 | Tuck end closing |

| 5 | Finished carton output |

Specifications

| Parameter | Value |

|---|---|

| Model | HL-ZC-G1 |

| Machine type | Servo tuck end box cartoning machine |

| Conveyor speed | 50–60 pcs/min |

| Carton size | L120–200 × W60–140 × H30–70 mm |

| Carton type | Tuck end paper box |

| Drive system | Full servo motor |

| Operation mode | Fully automatic |

| Power supply | 220V / 50Hz |

| Machine dimension | L3300 × W1250 × H1700 mm |

Production Line Integration

HL-ZC-G1 can work independently or be integrated with other packaging equipment.

| Equipment Type | Integration |

|---|---|

| Feeding device | Automatic product feeding |

| Filling machine | Product filling before cartoning |

| Labeling machine | Carton labeling |

| Weighing machine | Weight checking |

| Case packer | Secondary packaging |

This allows customers to build a complete automatic packaging production line.

Video

Click 👉:More Case Videos

Why Choose This Machine

| Advantage | Description |

|---|---|

| Stable performance | Designed for continuous operation |

| Packaging quality | Neat carton forming and closing |

| Flexibility | Suitable for various carton sizes |

| Automation | Reduces labor cost |

| Application | Suitable for multiple industries |

FAQ

Q: Is the HL-ZC-G1 suitable for small-batch production?

A: Yes—its flexible speed (3,000–4,800 pcs/h) adapts to both small-batch and mass output.

Q: How hygienic is this machine for food packaging?

A: It uses food-grade stainless steel and enclosed structure, fully meeting food hygiene standards.

Q: Can it integrate with my existing labeling machine?

A: Absolutely—it’s designed to connect with most mainstream upstream/downstream packaging equipment.

Contact Us

For detailed specifications, pricing, or packaging solutions, please contact us.

We will provide suitable recommendations according to your packaging requirements.

✉️Email: [email protected]

📞WhatsApp:+86

| Application Industry | Cosmetic, Electronic Product, Food, Medical Pharmaceutical |

|---|---|

| Products | Cartoning Machine |

Reviews

There are no reviews yet.