Smart Packaging Market to Surpass 400 Billion Yuan: Which Equipment Type Is Safer for SMEs to Enter?

Alyssa/October 16,2025 Return

The global smart packaging market is entering a golden growth period. Data shows that China’s smart packaging industry market size reached 25 billion dollars in 2024, with a year-on-year growth of 12.5%, and is expected to hit 28 billion dollars in 2025. Globally, the market is projected to exceed 40 billion US dollars by 2035, with the Chinese market alone likely to surpass 56 billion US dollars in scale. For small and medium-sized enterprises (SMEs) looking to enter this booming sector, choosing the right equipment category is crucial to reducing risks and ensuring steady development.

From a market demand perspective, semi-automatic smart labeling machines are an ideal entry point. In 2024, China’s smart label product market size reached 1.1 billion US dollars, accounting for 40.5% of the smart connected packaging market. Semi-automatic models, unlike fully automatic lines that require huge upfront investments, have lower initial costs (usually 7,000–21,000 US dollars per unit) and shorter payback periods (6–12 months). They are highly adaptable to small-batch, multi-variety production needs of SMEs, especially in industries like local food processing and small-scale pharmaceuticals. UBL Packaging’s HL-T series semi-automatic labeling machines, for instance, support quick parameter adjustments and can handle labels for bottles, boxes, and bags, perfectly matching the flexible production demands of SMEs.

Small intelligent bagging machines are another low-risk option. The food and beverage industry, which accounts for 38% of smart packaging equipment demand, has a massive need for small-batch packaging. Small intelligent bagging machines (such as UBL’s YH-A51D series) cost 11,000–28,000 US dollars, much less than large-scale automated production lines. They feature modular designs, allowing for easy upgrades to add functions like vacuum sealing or online printing as businesses grow. In 2024, the demand for smart packaging equipment in China’s food and beverage sector grew by 15.3%, and SMEs focusing on this segment can quickly capture regional market opportunities.

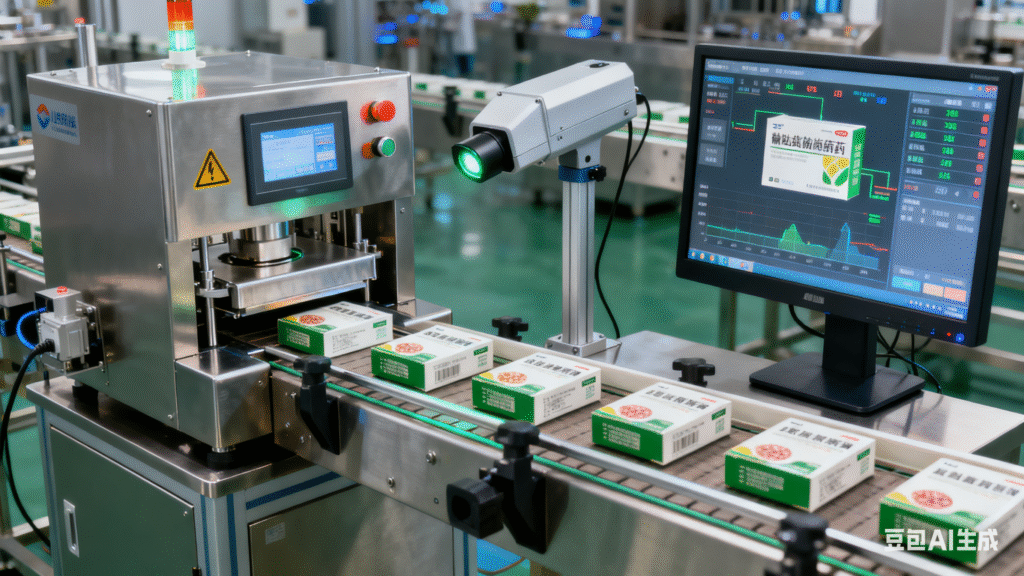

Smart detection and auxiliary equipment also offer promising prospects. As downstream industries raise requirements for packaging safety and traceability, smart detection devices like weight checkers and defect scanners are in increasing demand. These devices have low technical thresholds for entry, with average unit prices ranging from 4,200–14,000 US dollars. They can be easily integrated with SMEs’ existing production lines without major overhauls. In 2024, China’s smart detection and control system market size reached 1.1 billion US dollars, growing by 41.2% year-on-year, indicating strong market potential.

For SMEs, avoiding high-investment, high-risk areas is essential. Fully automatic smart packaging production lines, for example, require investments of over 1 million yuan and have complex after-sales maintenance needs, making them unsuitable for most SMEs. Instead, starting with semi-automatic labeling machines, small intelligent bagging machines, or smart detection equipment allows SMEs to accumulate technology, funds, and customer resources, laying a solid foundation for future expansion into higher-value segments.

In this market worth hundreds of billions, SMEs don’t need to compete head-on with large enterprises for large-scale projects. By focusing on niche needs like small-batch production and regional services, and choosing cost-effective, flexible equipment types, they can carve out a stable market share and grow alongside the smart packaging industry.

Newsletter Updates

Enter your email address below and subscribe to our newsletter