Your products deserve to arrive clean, fresh, and cared for — not covered in dust from the line. 🤍🌿

Alyssa/ November 20, 2025 Return

Have you seen this happen? Your bagging machine runs smoothly at the beginning, but after an hour or two, the pulling becomes slower, the opening action becomes unstable, and sometimes the suction cup can’t even grab the bag. Many operators suspect air pressure or film material issues, but the most common cause is actually much simpler —

dust buildup.

In food packaging, light industry, and e-commerce warehouses, tiny dust particles from film, paper, and general workshop activity float in the air. These particles slowly settle on key areas: sensors, suction cups, clamp edges, rail sides, and push-rod paths. When dust blocks these areas, movements become less responsive, sensors misread, and the entire rhythm of the machine is disrupted.

UBL’s bagging machines are designed for precision, which makes keeping them clean even more important.

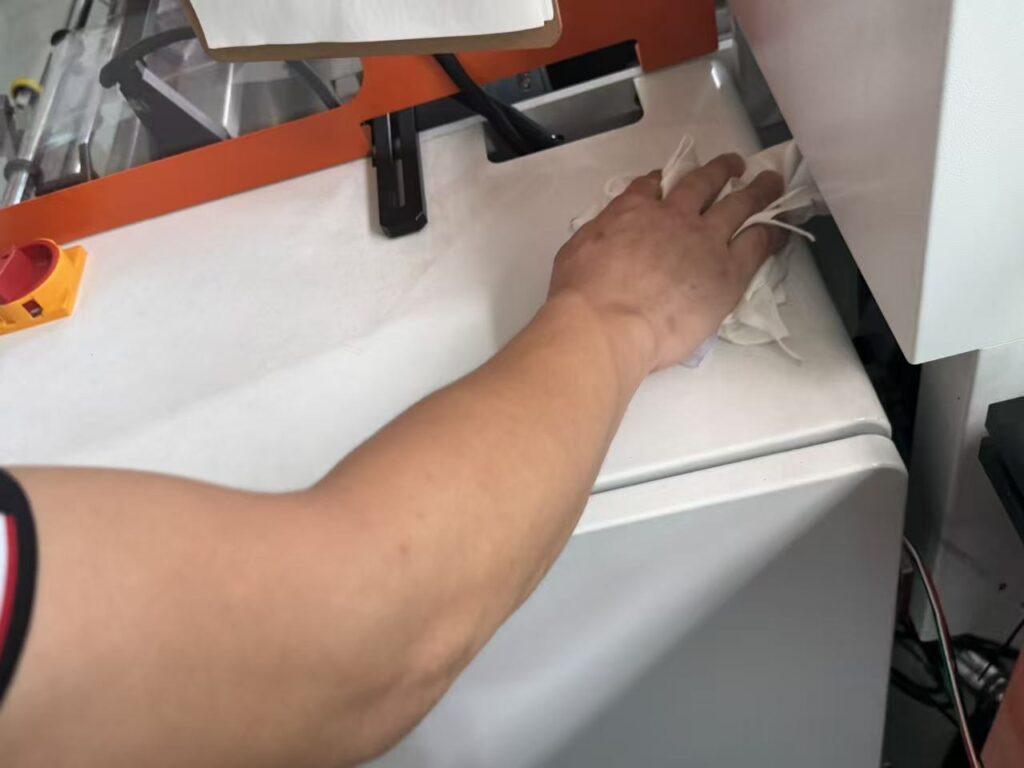

Luckily, the solution is extremely simple — a quick wipe. During shift changes or machine stops, gently clean the sensor surfaces, suction cup area, and clamp edges with a clean lint-free cloth. This small step often brings the machine back to full speed immediately. Many factories say, “Just wiping dust made the machine feel brand new again.”

If your bagging machine feels slower or less accurate than usual, take a moment to check for dust. Sometimes, solving the problem is as easy as wiping it away.

Do you wipe your machine daily? Tell me your industry, and I can help you identify which areas in your environment collect dust the fastest.