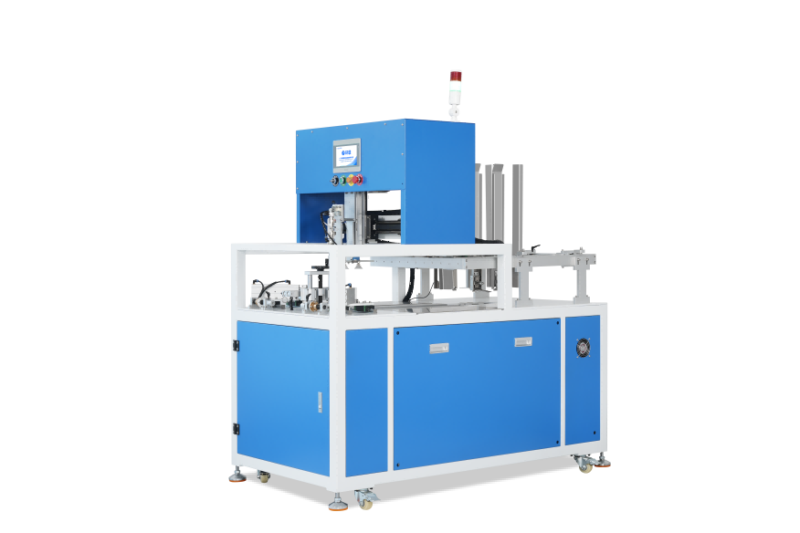

HL-ZK10S-D Vertical Self-Snap Lock Bottom Box Opening Machine

Product Description

The HL-ZK10S-D is a high-efficiency automatic snap lock bottom carton forming and folding machine designed to automate the opening and bottom-locking process of self-lock style cartons. Unlike standard RSC cases, snap-lock (crash-lock) boxes require precise mechanical coordination to secure the bottom flaps without tape or glue.

This high speed snap lock bottom box folding machine features a vertical design that saves floor space while providing a stable platform for forming large paper boxes. It is an ideal solution for industries requiring rapid, secure, and aesthetic packaging, transforming flat-packed blanks into ready-to-fill cartons in seconds.

Product Features

- Precision Self-Locking Mechanism: Specifically engineered for “crash-lock” or “snap-lock” bottom boxes, ensuring the bottom is securely fastened every time.

- High-Speed Operation: Capable of forming 780-1080 boxes per hour, significantly boosting the throughput of your packaging line.

- Vertical Space-Saving Design: The vertical orientation allows for a more compact footprint, making it easy to integrate into existing production environments.

- User-Friendly Interface: Equipped with an intuitive touch-screen control panel for easy adjustment of speeds and troubleshooting.

- Smooth Integration: Can be used as a standalone unit for manual loading or integrated into a fully automatic carton forming and folding line.

- Reliable Components: Built with high-quality pneumatic and electrical components to ensure 24/7 industrial durability.

Application

As a lock bottom carton machine for food, it handles snacks, confectionery, tea, and bottled products. The vertical design supports large paper boxes common in food multipacks, while the forming process avoids adhesive contamination risks.

Serving as a lock bottom box machine for cosmetics, it erects skincare sets, perfume boxes, and facial mask cartons. The precise folding mechanism preserves high-end printed finishes during rapid forming.

As a pharmaceutical snap lock bottom folding machine, it ensures consistent assembly of medicine bottles and diagnostic kit boxes, meeting demands for clean, reliable packaging at speeds up to 1,080 cartons/hour.

Handles sturdy large-format cartons for electronic accessories and toys, providing a self-locking bottom that supports product weight without additional taping—ideal for retail-ready packaging.

Integrated into automated lines, it offers a sustainable, tape-free solution for shipping boxes and subscription services, reducing material costs and packaging time.

Working Process

- Magazine Loading: Flat self-snap lock carton blanks are manually placed into the vertical high-capacity magazine.

- Suction & Extraction: The machine’s suction system pulls one blank at a time and opens it into a rectangular carton shape.

- Bottom Folding & Self-Snap Locking: Mechanical arms fold the carton bottom flaps in sequence, completing the self-snap lock (1-2-3) mechanism to secure the bottom without tape or glue.

- Discharge: The fully formed carton is automatically conveyed to the manual box loading platform or connected production line for subsequent filling.

Technical Specifications

| Item | Specification |

|---|---|

| Model | HL-ZK10S-D |

| Machine Name | Vertical Self-Snap Lock Bottom Box Opening Machine |

| Opening Speed | 780 – 1080 pcs/h |

| Power Supply | 220V, 50Hz, 0.6kW |

| Air Consumption | 600NL/min, 0.6 – 0.8MPa |

| Machine Size (L×W×H) | 1700 × 1500 × 1300 mm |

| Machine Weight | 350 Kg |

Video

Click 👉:More Case Videos

FAQ

Q1: What is a “Snap Lock Bottom” box?

A: It is a type of carton where the bottom flaps are die-cut to interlock with each other during the opening process, requiring no tape or glue to stay closed.

Q2: Can this machine handle different box sizes?

A: Yes, the machine is adjustable. You can quickly reconfigure the guides to accommodate various box dimensions within the machine’s range.

Q3: Does it require a specialized operator?

A: No. Once the parameters are set, the operator only needs to load the flat carton blanks into the silo. The machine handles the rest automatically.

Q4: Is it compatible with an e-commerce workflow?

A: Absolutely. It is a core component for any E-commerce Packaging Snap Lock Bottom Carton Line, helping to speed up the fulfillment of boxed goods.

Contact Us

For detailed specifications, pricing, or packaging solutions, please contact us.

We will provide suitable recommendations according to your packaging requirements.

✉️Email: [email protected]

📞WhatsApp:+86

| Products | Carton Folding Machine |

|---|---|

| Application Industry | Food, Hardware, Medical Pharmaceutical |

Reviews

There are no reviews yet.