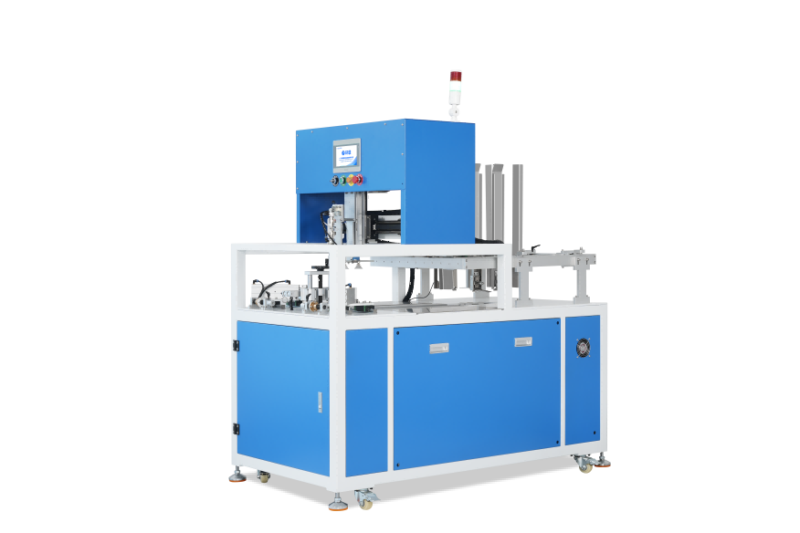

HL-ZK10 Automatic Snap Lock Bottom Carton Erecting Machine

The HL-ZK10 Automatic Snap Lock Bottom Box Erector enables rapid, automated forming of 1-2-3 bottom cartons from magazine pickup to bottom locking, ensuring consistent quality and labor savings, and is widely applied in food, cosmetic and pharmaceutical industries.

Product Description

The HL-ZK10 Automatic Snap Lock Bottom Carton Erecting Machine is a robust industrial solution designed to automate the forming of heavy-duty snap-lock (crash lock) boxes. Unlike standard folding machines, the HL-ZK10 is specifically engineered to handle the structural demands of industrial goods, automotive parts, and household appliances. By automating the bottom-locking sequence, it ensures each carton is perfectly squared and structurally sound, providing a reliable packaging foundation for products that require extra support during transit.

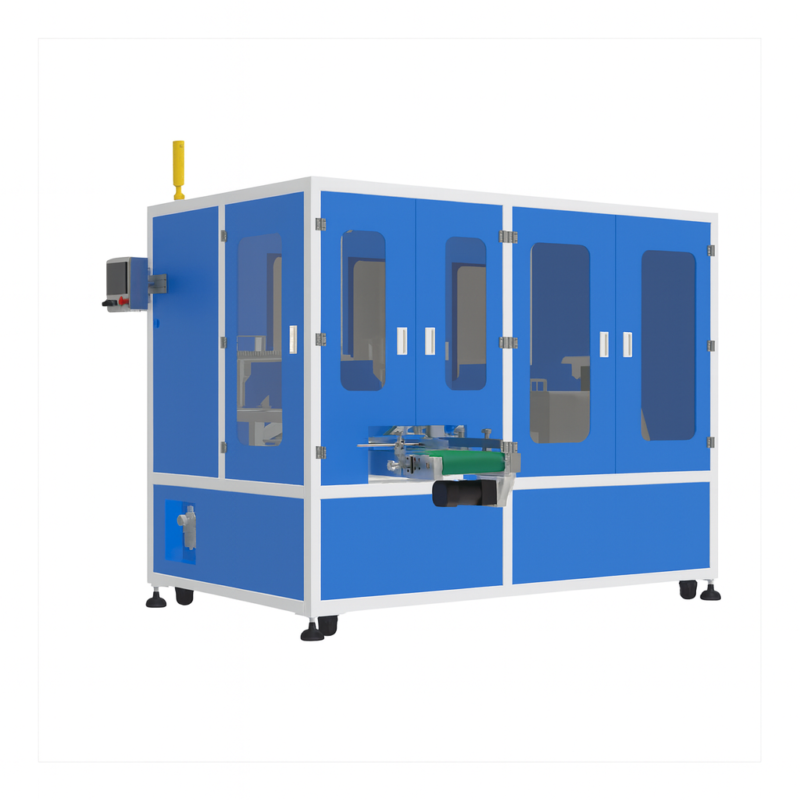

Product Features

- Reliable Bottom Locking: Precision mechanical arms “buckle” the bottom flaps into a secure, interlocking structure, providing superior weight-bearing capacity for heavy products.

- Dual-Suction Opening: Equipped with a powerful vacuum system that ensures positive box opening from the magazine, even for recycled or heavy-duty paperboard.

- Parameter Memory Function: Features an intelligent PLC system that can store formulas for different box sizes, allowing for a 5-minute rapid changeover using calibrated handwheels.

- Durable & Low Maintenance: Built with high-quality components to ensure a low failure rate and long-term stability in 24/7 production environments.

- Compact Footprint: Its space-saving design (1620mm length) allows it to be easily integrated into existing packing lines or used as a standalone workstation.

Application

The HL-ZK10 Automatic Snap Lock Bottom Carton Erecting Machine is engineered for industries where structural box integrity and presentation are paramount:

- Electronics & Small Appliances: Perfectly suited for packaging hair dryers, electric kettles, and vacuum cleaners, providing a reinforced bottom that safely supports the product’s weight.

- Automotive Parts & Filters: Ideal for the industrial sector, including oil filters, spark plugs, and car accessories, where durable and consistent carton forming is required for shipping.

- Household Goods & Thermos Cups: Provides a clean, professional look for insulated mugs, kitchenware, and home decor items, ensuring the box remains perfectly square and retail-ready.

- Toys & E-commerce: Supports high-volume fulfillment for action figures, board games, and subscription boxes, reducing labor costs while increasing throughput.

- Personal Care & Beauty: Handles high-end printed cartons for skincare sets and gift boxes without scratching or damaging the delicate surface finish.

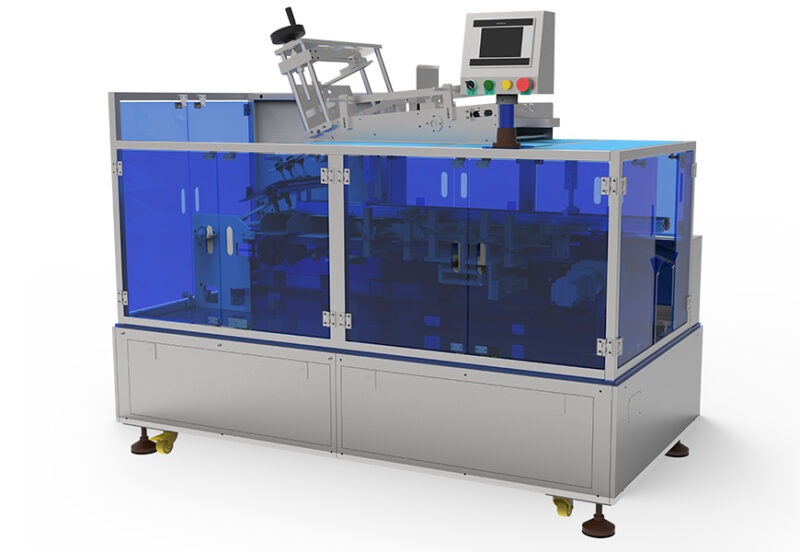

Working Process

- Magazine Feeding: Flat-packed buckle bottom blanks are loaded into the vertical hopper.

- Vacuum Extraction: Dual suction cups pull a single blank and expand it into a rectangular shape.

- Mechanical Buckling: The machine’s folding fingers precisely tuck and lock the bottom flaps in a synchronized sequence.

- Forming & Output: The fully erected box, with its bottom securely locked, is discharged onto the conveyor for product loading.

Technical Specifications

| Specification | HL-ZK10 (Standard) | HL-ZK10B (Large) |

|---|---|---|

| Model Number | HL-ZK10 | HL-ZK10B |

| Core Function | Snap Lock Bottom Erecting | Snap Lock Bottom Erecting |

| Speed | 720 – 950 pcs/h | 700 – 900 pcs/h |

| Box Size (L) | 100 – 300 mm | 120 – 300 mm |

| Box Size (W) | 70 – 120 mm | 100 – 240 mm |

| Box Size (H) | 70 – 120 mm | 70 – 150 mm |

| Power Supply | 220V 50Hz / 0.5kW | 220V 50Hz / 0.5kW |

| Air Consumption | 0.6 – 0.8 Mpa | 0.6 – 0.8 Mpa |

| Machine Weight | 350 kg | 380 kg |

Video

Click 👉:More Case Videos

FAQ

Q: Is the HL-ZK10 suitable for heavy automotive parts?

A: Yes. The HL-ZK10 is specifically designed for snap-lock (buckle bottom) boxes which offer superior weight-bearing capacity compared to standard tuck-top boxes, making it ideal for filters and car parts.

Q: How does the “Parameter Memory” help in production?

A: It allows you to save the settings for different box sizes (e.g., one for hair dryers and one for thermos cups). When you switch products, the machine recalls the settings, reducing downtime to under 5 minutes.

Q: Can this machine handle customized box sizes?

A: Absolutely. While we have Standard and Big models, we can customize the machine range to fit your specific carton dimensions.

Contact Us

For detailed specifications, pricing, or packaging solutions, please contact us.

We will provide suitable recommendations according to your packaging requirements.

✉️Email: [email protected]

📞WhatsApp:+86

| Products | Carton Folding Machine |

|---|---|

| Application Industry | Cosmetic, Electronic Product, Food, Hardware, Medical Pharmaceutical |

Reviews

There are no reviews yet.