IoT Remote Maintenance Reduces Packaging Equipment Downtime

IoT remote maintenance has quickly become one of the most effective ways for packaging manufacturers to control downtime—and the costs that come with it.

Unplanned downtime rarely arrives with a warning.

For small and mid-sized packaging workshops, a single machine failure can trigger missed delivery windows, overtime labor, and expensive emergency service visits.

As the packaging industry moves deeper into Industry 4.0, more manufacturers are stepping away from the old “fix it after it breaks” mindset. Instead, IoT-powered remote maintenance is helping turn maintenance into a preventive, data-driven process.

Why Traditional Maintenance Falls Short

The biggest weakness in traditional maintenance is visibility.

Machines often appear fine on the surface, while internal components are already under stress. Without real-time data, problems stay hidden until production suddenly stops.

With IoT remote maintenance, sensors installed on packaging equipment—such as cartoning machines, sealing systems, and filling lines—continuously monitor key indicators like:

- Vibration

- Temperature

- Motor load

- Energy consumption

This data is transmitted to a cloud-based dashboard, allowing abnormal behavior to be detected early—before it turns into downtime.

In one snack packaging operation using IoT-enabled equipment, abnormal motor vibration was identified remotely. Engineers adjusted operating parameters within minutes, avoiding a full shutdown and preventing thousands of dollars in production losses.

Predictive Maintenance Beats Guesswork

Scheduled maintenance often leads to wasted effort. Parts get replaced “just in case,” and machines are stopped even when no real issue exists.

IoT remote maintenance enables predictive maintenance instead:

- Sensor data highlights early signs of wear

- Maintenance is triggered only when real risk appears

- Spare parts and labor are used more efficiently

According to McKinsey & Company, predictive maintenance can reduce machine downtime by 30–50% while lowering maintenance costs by up to 40% in industrial environments .

For packaging manufacturers, that means fewer idle technicians, lower spare-parts inventory, and far more predictable operating costs.

Remote Support Cuts Service Delays and Travel Costs

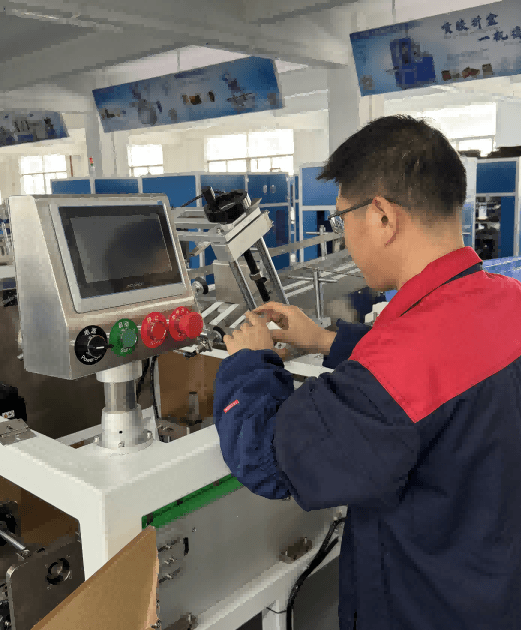

Not every issue can be solved automatically—but IoT drastically reduces how often experts need to be on-site.

With remote support and AR-assisted guidance, on-site operators can share live video with off-site engineers. Step-by-step instructions are overlaid directly onto the machine view, making troubleshooting faster and more accurate.

In one bakery packaging line, a jammed cartoning machine was resolved in under an hour using remote guidance. Previously, the same issue required an all-day wait for a service technician to arrive.

For factories running tight delivery schedules, that time difference matters.

The Numbers Back It Up

Industry research continues to confirm the value of IoT remote maintenance. Studies from the International Society of Automation show that connected maintenance systems can cut unplanned downtime by more than half while significantly reducing overall maintenance spending .

For manufacturers using IoT-ready packaging equipment, these gains are no longer limited to large factories. Modern systems are designed with low-power sensors and modular connectivity, making smart maintenance accessible even for smaller workshops.

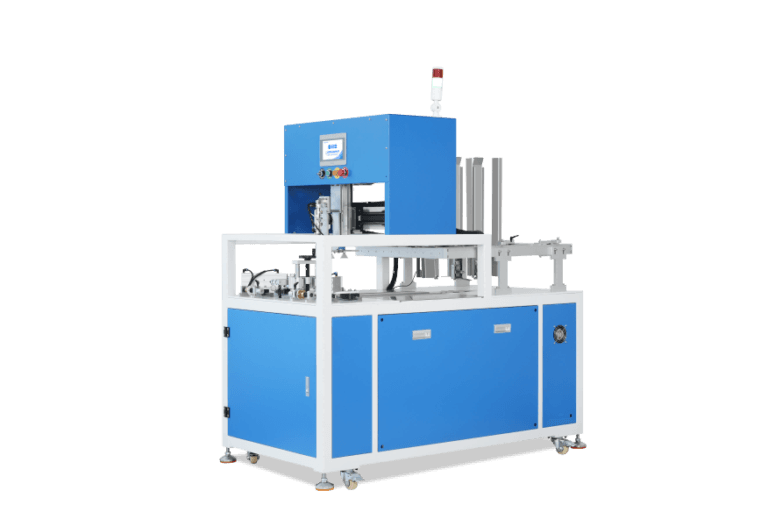

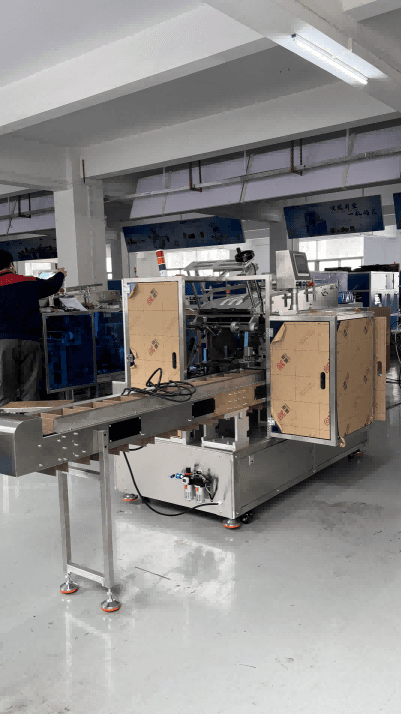

Where Cartoning Machines Fit In

Secondary packaging equipment is often one of the best starting points for IoT adoption.

Cartoning machines operate continuously, experience frequent format changes, and directly affect shipping schedules. Connecting them to an IoT remote maintenance system delivers immediate visibility and faster response times.

If you want to explore how connected secondary packaging fits into modern production lines, you can learn more about our cartoning machine solutions designed for smart, data-driven operations.

IoT Remote Maintenance Is No Longer Optional

IoT remote maintenance is no longer a future concept—it’s a practical cost-control tool available today.

By turning packaging equipment into connected assets, manufacturers can reduce unexpected downtime, optimize maintenance resources, and keep production running smoothly without inflating service budgets.

Ready to Reduce Downtime the Smart Way?

Every packaging operation faces different challenges. Whether you’re dealing with frequent stoppages or rising service costs, IoT-enabled maintenance may be the smarter next step.

Contact us today.

We will reach out within 24 hours, review your needs, and connect you directly with our engineers—so they can design an IoT-ready packaging solution that fits your production line as quickly as possible.

reference material

【1】McKinsey & Company – Predictive Maintenance & Industry 4.0

【2】International Society of Automation (ISA) – Industrial IoT & Smart Maintenance