Why a “Lower-Cost” Carton Folding Machine Often Costs More Over Time

When manufacturers compare a carton folding machine, most attention goes to the purchase price.

It’s understandable—but it’s also risky.

The real cost of a carton folding machine is not what you pay on day one. It’s what you keep paying every day after: electricity, carton waste, maintenance labor, downtime, and lost output. Together, these define the Total Cost of Ownership (TCO)—and this is where many “low-cost” machines quietly become expensive.

Energy Inefficiency

Low-price carton folding machines often use outdated motors or simplified drive systems. They work—but not efficiently.

That leads to:

- Higher electricity consumption per carton

- More heat and mechanical stress

- Rising energy bills on long production runs

On a secondary packaging line running two or three shifts, energy waste compounds quickly. Over a year, this hidden cost can exceed the initial savings of a cheaper machine.

According to U.S. food manufacturing efficiency guidelines, energy efficiency is one of the primary contributors to long-term operational cost control in packaging operations .

Carton Waste From Inconsistent Folding

Precision matters in carton folding.

When folding accuracy fluctuates, factories see:

- Crooked carton formation

- Bottom-lock failures

- Increased use of tape or adhesive

- Rejected cartons during cartoning

Each rejected carton looks small on its own. Across tens of thousands of units per day, material waste becomes a structural cost problem.

A stable carton folding machine minimizes waste by keeping forming accuracy consistent—shift after shift.

Downtime and Human Intervention

Cheap machines rarely fail dramatically. They fail frequently.

Small jams. Minor misalignments. Repeated manual adjustments.

These interruptions:

- Reduce effective output

- Increase labor dependency

- Disrupt downstream equipment like cartoning and bagging

Over time, supervisors stop trusting schedules, and more people are added just to “keep things moving.” Labor becomes a buffer for machine instability—and labor is never cheap.

Why TCO Matters More Than Speed

Many buyers focus on maximum speed.

But speed without stability increases risk.

The real question is not:

“How fast can this carton folding machine run?”

It is:

“How consistently can it run without intervention?”

For secondary packaging—where folded cartons feed directly into a cartoning machine—stability is what protects the entire line.

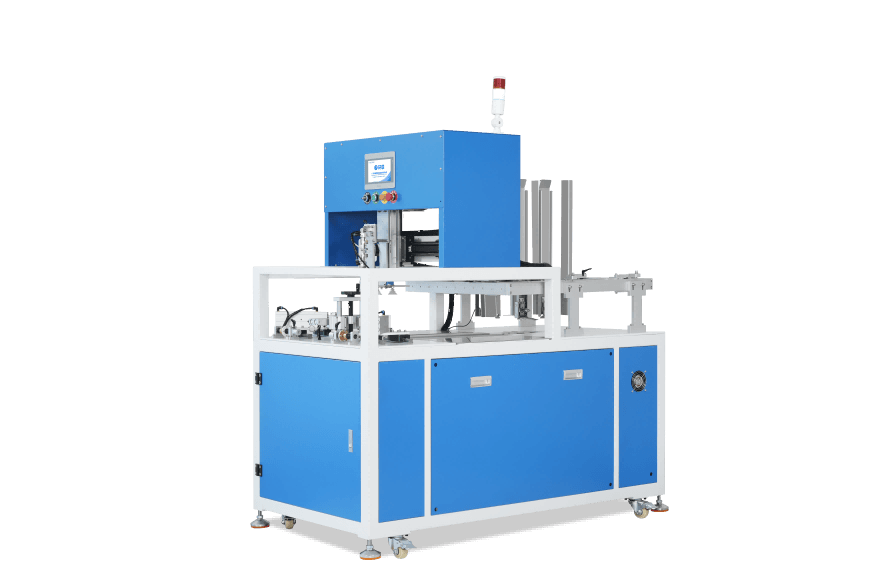

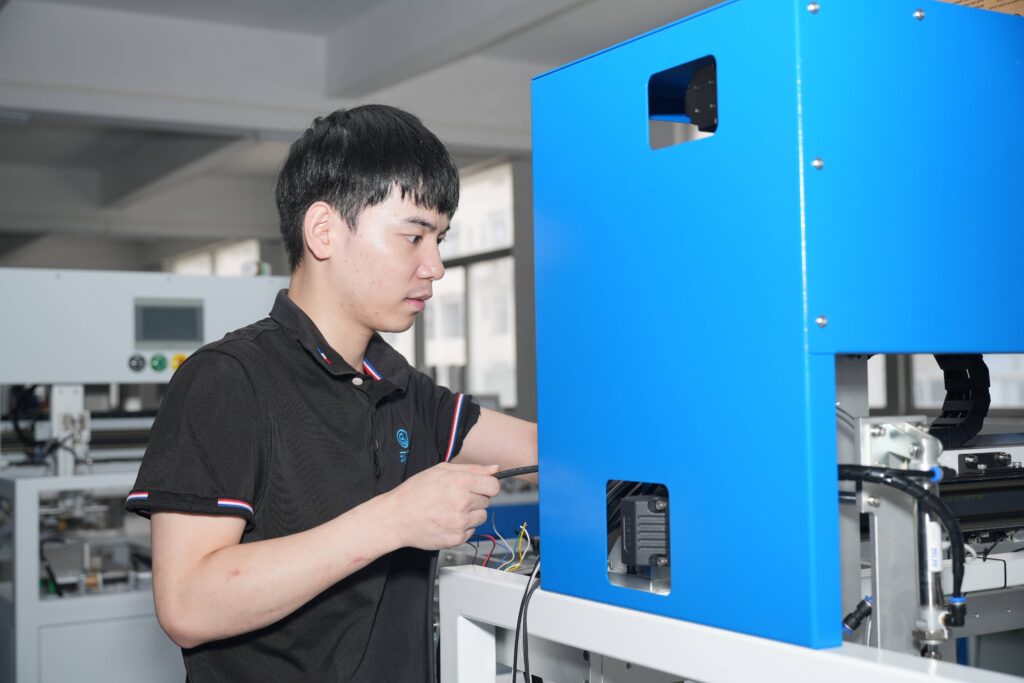

How UBL Designs Carton Folding Machines for Lower TCO

UBL carton folding machines are engineered around lifecycle cost, not just output speed.

Key design priorities include:

- Servo-driven motion for lower energy consumption

- High-precision carton forming to keep waste below 1%

- Modular mechanical structures for faster maintenance

- PLC monitoring to catch issues before they cause downtime

This approach is especially valuable for snap-lock bottom carton folding machines, where precision directly affects both material usage and cartoning stability.

Cost Is Not What You Pay — It’s What You Keep Paying

A low-price carton folding machine may look attractive in procurement.

But after months of operation, the real cost appears in:

- Energy bills

- Waste reports

- Downtime logs

- Labor schedules

Smart manufacturers evaluate Total Cost of Ownership, not just initial price.

That’s why more food factories upgrading their secondary packaging lines choose stable, automation-focused solutions—so costs stay predictable as volume grows.

Call to Action

If your folding section creates waste, downtime, or pressure on cartoning, the problem is not labor—it’s stability.

👉 Talk to our automation team

We help food factories design secondary packaging solutions covering carton folding, cartoning, weighing, inspection, labeling, bagging, and end-of-line automation.