Messy Packaging Workshop? Plan the Assembly Line This Way to Boost Efficiency by 30%

Alyssa/October 4,2025

A disorganized packaging workshop—with scattered cartons, tangled material shelves, and workers crisscrossing to fetch supplies—not only increases the risk of accidents but also drags down overall efficiency. According to a 2024 Global Logistics Workshop Survey, messy workshops waste 15-20% of workers’ daily time on searching for materials or avoiding obstacles. The solution lies in scientific assembly line planning: by optimizing layout, material flow, and space usage, enterprises can typically boost efficiency by 30% or more, as proven by practices from leading manufacturing and e-commerce companies.

Step 1: Layout Planning—Choose the Right “Shape” for the Assembly Line

The first step to end chaos is designing a logical assembly line layout. Two layouts have proven most effective for packaging workshops:

1. U-Shaped Assembly Line: Minimize Movement, Maximize Collaboration

The U-shaped layout clusters packaging stations (box erecting, filling, sealing, labeling) in a U formation, with material storage at the open end. This design cuts down worker movement distance by 40%—workers no longer need to walk across the workshop to fetch supplies. A U.S. e-commerce fulfillment center redesigned its 5 packaging lines into U-shapes and found that workers’ average daily walking distance dropped from 8km to 3.5km, freeing up 1.5 hours daily for actual packaging work.

Key tip: Place high-frequency materials (e.g., tape, labels) at the “inside curve” of the U, within arm’s reach of operators.

2. Linear Layout with Clear Zones: For High-Volume, Single-Product Lines

For workshops focused on a single type of product (e.g., auto parts packaging), a linear layout with dedicated zones works better. Divide the line into 4 clear zones:

- Material Inbound Zone: Unload and store raw materials (cartons, cushioning) near the workshop entrance.

- Packaging Operation Zone: Arrange stations in sequence (erect → fill → seal → label) with 1.2-1.5m of space between stations to avoid crowding.

- Quality Check Zone: Place after the last packaging station to inspect finished products without blocking the line.

- Finished Goods Outbound Zone: Locate near the workshop exit for quick loading.

A German automotive parts supplier adopted this layout and reduced cross-traffic collisions by 70%, while packaging speed increased by 25%.

Step 2: Material Flow Optimization—Eliminate “Back-and-Forth” Waste

Messy material flow is the biggest hidden efficiency killer. Follow these two principles to streamline it:

1. “First-In-First-Out (FIFO)” Material Shelves + Clear Labeling

Replace random material piles with FIFO shelves, labeled with:

- Material name (e.g., “20cm×15cm Cartons”)

- Quantity (e.g., “500pcs Remaining”)

- Location code (e.g., “Shelf A3-2”)

A UK electronics packaging workshop implemented this and cut material-searching time from 12 minutes per hour to 3 minutes. Additionally, color-coding labels (e.g., red for urgent materials, blue for regular) helps workers identify supplies at a glance.

2. Automated Material Conveyors: Connect Zones Seamlessly

For medium-to-large workshops, add belt conveyors between stations to move semi-finished products automatically. Avoid manual carrying—this reduces material damage (by 30% on average) and worker fatigue. A Canadian furniture packaging plant installed 10m-long conveyors between filling and sealing stations, and saw a 18% increase in hourly output, as workers no longer had to carry heavy cartons.

Step 3: Space Utilization—Make the Most of Vertical and Corner Space

Wasting vertical space is a common mistake in messy workshops. Use these tricks to expand usable space:

1. Vertical Storage Racks: Double Storage Capacity

Install 3-4m tall adjustable storage racks for lightweight materials (e.g., bubble wrap, labels). Equip racks with stair-step shelves or pull-out drawers to avoid “hard-to-reach” corners. A Singapore-based toy packaging workshop added vertical racks and reduced floor space used for storage by 50%, freeing up area for an extra packaging line.

2. Corner Workstations: Turn Dead Space into Productive Zones

Utilize workshop corners for auxiliary stations (e.g., label printing, minor repair) instead of leaving them as junk piles. Install foldable tables that can be 收起 when not in use to save space. A Japanese packaging factory transformed 4 corners into label stations and reduced the need for workers to walk to a central printing area, saving 20 minutes per shift.

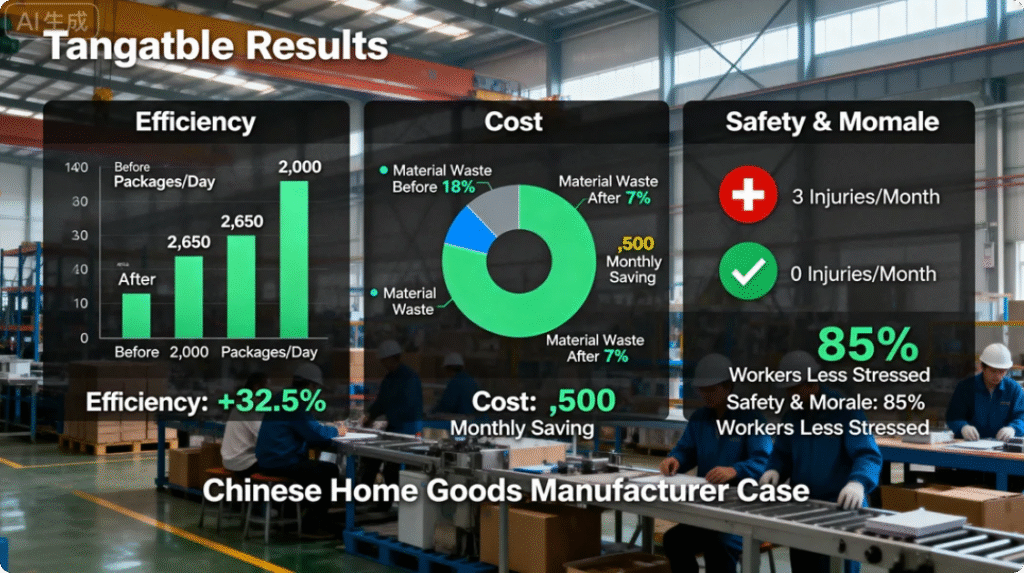

Tangible Results: Efficiency Boost Beyond Numbers

A Chinese home goods manufacturer once struggled with a messy 800㎡ packaging workshop: daily output was 2,000 packages, with 3 worker injuries monthly and 18% material waste. After 1 month of implementing the above planning:

- Efficiency: Daily output rose to 2,650 packages—a 32.5% increase, exceeding the 30% target.

- Cost: Material waste dropped to 7%, saving $4,500 monthly; worker injury rate fell to zero.

- Morale: A post-implementation survey showed 85% of workers felt “less stressed” and “more focused” in the organized environment.

Scientific assembly line planning isn’t just about “tidying up”—it’s about redesigning the workshop to minimize waste, maximize flow, and make every square meter and every minute count. For workshop managers, this is a low-cost, high-return way to turn chaos into order and inefficiency into productivity.

Newsletter Updates

Enter your email address below and subscribe to our newsletter