3 Essential Features Every Snap Lock Bottom Box Erector Should Have

In today’s competitive manufacturing and e-commerce environment, packaging is no longer just a final step—it’s a strategic advantage. Details like box forming accuracy and Snap Lock Bottom locking strength directly affect shipping safety, warehouse efficiency, and brand perception.

Manual box folding and bottom locking might seem manageable at small volumes. But once orders scale up, the weaknesses quickly show:

- Inconsistent bottom closure

- Boxes collapsing under weight

- Slow production speeds

- High labor costs

- Increased product damage during transport

If your business is aiming for scalable growth, investing in a high-performance Snap Lock Bottom box erector is no longer optional—it’s essential.

Here are the three must-have features to look for when choosing the right system.

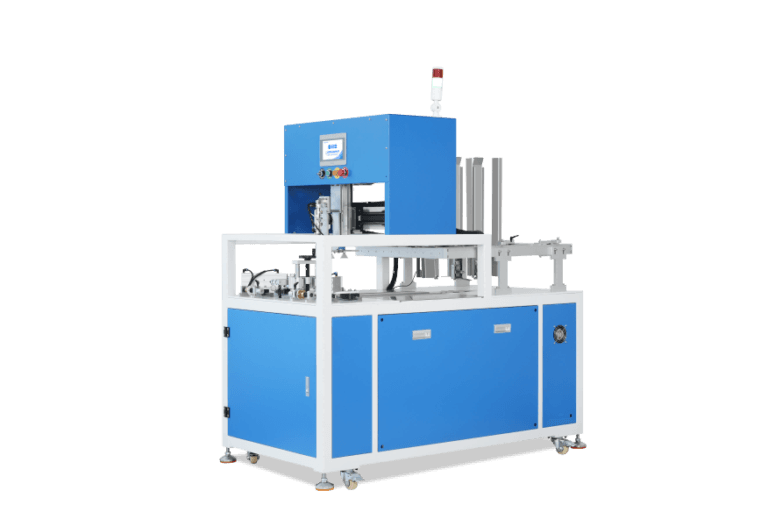

Fully Automatic Precision Forming and Bottom Locking

A professional Snap Lock Bottom box erector should do more than just open a carton. It must precisely form and securely lock the bottom structure in one continuous, synchronized motion.

Using flat carton blanks, the machine should automatically:

- Open and square the box accurately

- Fold and interlock the Snap Lock Bottom flaps

- Ensure tight, secure bottom engagement

- Deliver uniform forming quality across every cycle

This is especially critical for industries such as:

- Food and beverage

- Cosmetics and personal care

- Pharmaceutical packaging

- E-commerce fulfillment

When the bottom is locked correctly every single time, the box can immediately move to filling or shipping without additional inspection or manual correction.

Precision forming not only reduces labor—it eliminates rework, minimizes defects, and protects your products during transport.

High-Speed, Stable Operation with Long-Term Reliability

Speed matters. But stability matters more.

A high-quality Snap Lock Bottom box erector should be capable of producing thousands of boxes per hour—without sacrificing forming accuracy.

At UBL, every machine undergoes a 168-hour continuous run test before shipment. This extended stability testing ensures consistent performance and high MTBF (Mean Time Between Failures).

Key performance features include:

Multi-axis servo drive system for synchronized movement

PLC intelligent control for precise timing

High-precision sensors for accurate positioning

Reinforced mechanical frame for vibration reduction

The result?

Reduced downtime

Lower maintenance costs

Fewer mis-formed cartons

Consistent bottom locking strength

In high-volume operations, even small inefficiencies multiply quickly. A stable Snap Lock Bottom box erector protects your uptime and your profit margins

Flexible Compatibility for Multiple Box Sizes

Most production lines don’t run a single box size forever. Seasonal products, promotional packaging, and new SKUs require flexibility.

A modern Snap Lock Bottom box erector must support:

Fast size changeovers

Adjustable forming parameters

Quick width and length modifications

Minimal downtime between runs

With a user-friendly touchscreen interface, operators can:

Save multiple box configurations

Switch production modes efficiently

Monitor real-time operational data

This adaptability allows manufacturers to handle both mass production and short-run customization without purchasing multiple machines.

Flexibility is no longer a bonus—it’s a requirement.

Engineering Details That Make the Difference

Beyond the three core capabilities, the true value of a Snap Lock Bottom system lies in its engineering details.

Reinforced Structural Design

A rigid machine frame reduces vibration during operation, ensuring precise folding and locking alignment even at high speeds.

High-Precision Mechanical Components

Tight tolerances minimize wear, reduce mechanical deviation, and maintain forming accuracy over time.

Advanced Electrical Integration

Modern systems are designed for seamless integration with automated production lines, allowing smart monitoring, data tracking, and remote diagnostics.

These seemingly small design elements significantly improve:

Operational stability

Packaging consistency

Long-term durability

Total cost of ownership

Turning Packaging Automation into Profit

A well-designed Snap Lock Bottom box erector does more than automate carton forming—it directly contributes to profitability.

By combining:

Precision forming

High-speed stable operation

Flexible multi-size compatibility

your packaging line becomes faster, more reliable, and more cost-efficient.

Instead of depending on manual labor and inconsistent bottom locking, you gain a repeatable, scalable system that supports business growth.

Why UBL?

At UBL, we understand that every product has unique packaging requirements. That’s why our Snap Lock Bottom solutions are engineered around your specific box dimensions, material characteristics, and production targets.

From initial consultation to machine commissioning, our team ensures that your Snap Lock Bottom box erector is perfectly matched to your workflow.

If you’re ready to improve packaging efficiency, reduce labor dependency, and strengthen bottom closure performance, now is the time to upgrade.

Contact UBL today and share your carton specifications.

Let us design a solution that fits your production goals—precisely and reliably.