Smart Packaging Solutions

We deliver intelligent, automated packaging solutions that boost efficiency, optimize performance, and drive real business value.

UBL Packaging Solutions

At UBL, we provide smart, automated packaging solutions designed to meet the diverse needs of modern manufacturing industries. By combining advanced packaging equipment, intelligent control systems, and flexible customization, we help customers improve efficiency, reduce operational costs, and ensure consistent packaging quality.

Our solutions cover the full packaging process—from primary packaging to secondary and end-of-line automation—and are widely applied across industries such as food & beverage, pharmaceuticals, chemicals, consumer goods, and industrial products.

With strong engineering capabilities and a customer-focused approach, UBL delivers reliable, scalable, and future-ready packaging solutions that adapt to evolving production demands and support long-term business growth.

Why Smart Packaging Matters

Labor Costs & Workforce Pressure

In industries such as food & beverage, pharmaceuticals, and consumer goods, labor-intensive packaging is becoming increasingly challenging. High turnover, rising wages, and continuous training make manual operations costly and unpredictable. Intelligent packaging automation reduces dependency on labor and allows for stable, scalable production.

Packaging Efficiency & Delivery Reliability

Meeting growing order volumes and fluctuating demand is a major challenge in e-commerce, food, and industrial product packaging. Manual processes are slow, error-prone, and inconsistent, which can lead to missed shipments, poor product presentation, and delayed deliveries. Automated systems increase throughput, improve precision, and ensure consistent quality.

Digital Integration & Production Visibility

Many manufacturing environments, from pharmaceuticals to chemicals and electronics, still rely on standalone equipment with limited data connectivity. This creates “black boxes” in the production line, making real-time monitoring and decision-making difficult. Smart packaging integrates digital controls and data capture, providing visibility and actionable insights across the production process.

Space Utilization & Resource Efficiency

Packaging areas often occupy excessive floor space, and inefficient use of cartons, bags, and other materials increases waste. This is especially noticeable in consumer goods, industrial products, and logistics-heavy operations. Compact, modular line designs and precise material handling maximize space and minimize waste.

Enter UBL Smart Packaging

Across these challenges, UBL’s smart packaging solutions bring together automation, precision, and digital integration to help manufacturers reduce labor dependency, increase throughput, gain full visibility, and optimize space and material use. In short, UBL enables smarter, more efficient, and more reliable packaging operations—helping businesses meet the demands of modern manufacturing.

UBL Core Capabilities

Box Erecting Solution

As an intelligent packaging automation specialist, UBL delivers professional packaging box folding solutions for a wide range of box structures used across food, consumer goods, e-commerce, cosmetics, and industrial applications.

Each packaging box type has its own forming logic, size range, and structural requirements. UBL develops dedicated machines for each box style to ensure stable forming, high efficiency, and consistent output quality.

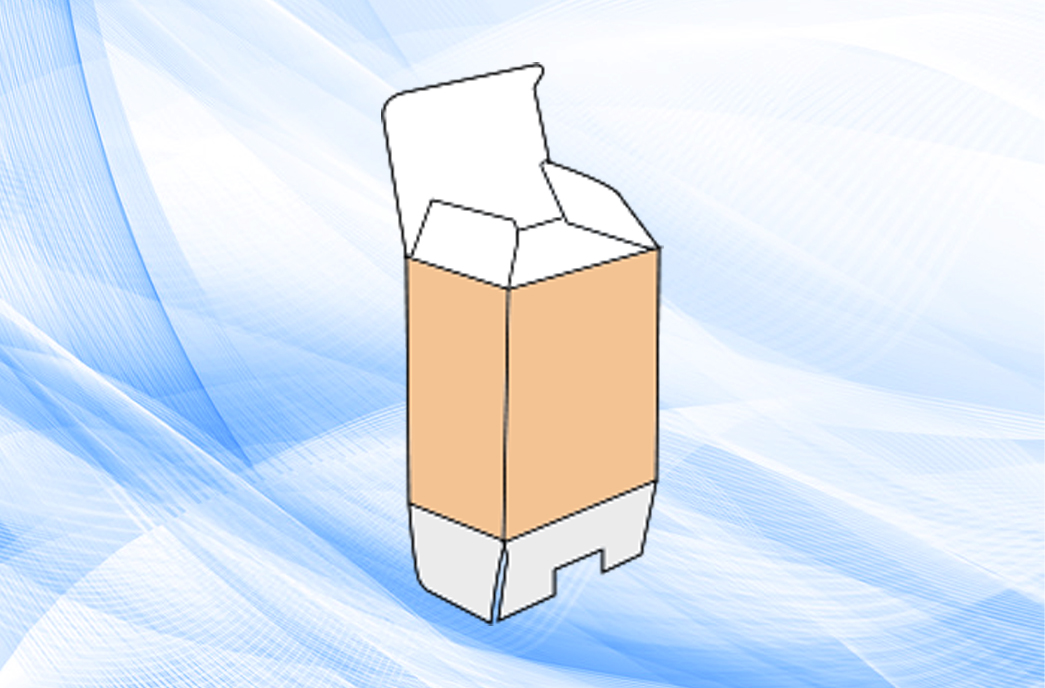

Snap Lock Bottom / Auto-Lock Box Solutions

For Snap Lock Bottom (Auto-Lock) packaging boxes, UBL recommends the HL-ZK10 Automatic Snap Lock Bottom Carton Erecting Machine, a machine specifically engineered for this box structure.

Box type: Snap Lock Bottom / Auto-Lock Box

Production speed: 720-950 boxes/h

Footprint(L*W*H): Approx. 1620*820*1650mm

Typical applications: Hair dryer packaging boxes, electric shaver boxes, coffee stick boxes, small appliance packaging, and various retail packaging boxes used in e-commerce

As long as the packaging box uses a snap lock bottom structure and falls within the supported size range, the HL-ZK10 can form it automatically with stable output and minimal manual involvement.

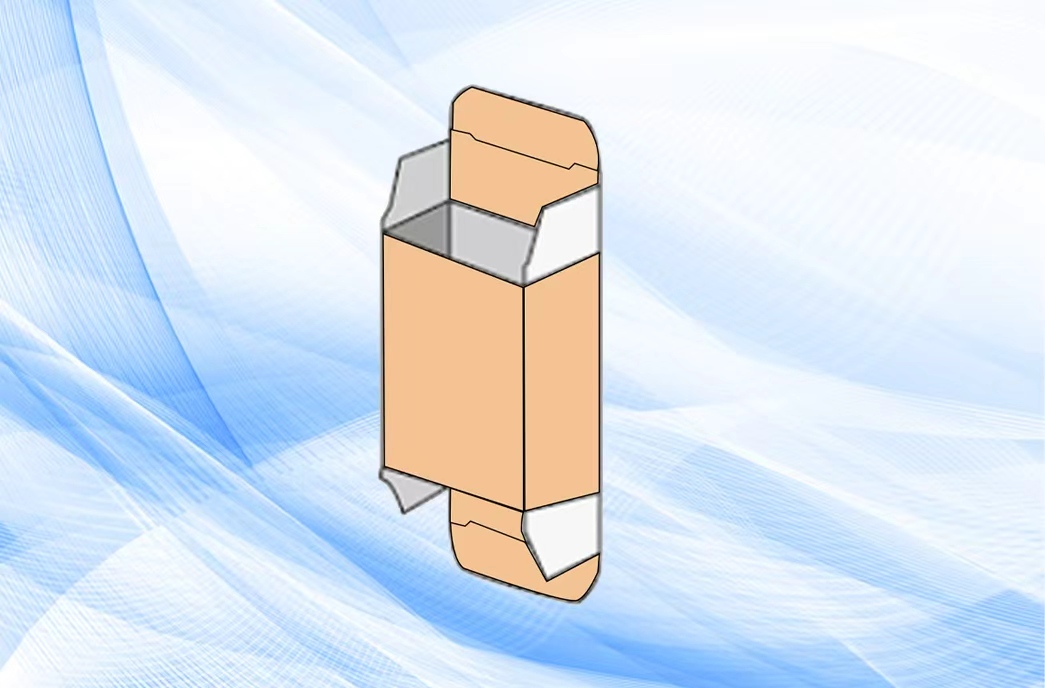

Tuck End Box (STE / RTE) Solutions

For Tuck End Boxes (Straight Tuck End / Reverse Tuck End), UBL recommends the HL-ZK10C-D Fully Automatic Tuck End Box Opening Machine.

This machine is designed to open and form tuck end packaging boxes with high accuracy, ensuring clean folds and proper alignment of the tuck flaps.

Box type: Tuck End Box (STE / RTE)

Production speed: 1800-3600 boxes/h

Footprint(L*W*H): Approx. 1900*1000*1600mm

Typical applications: Cosmetic packaging boxes such as face cream boxes, hand cream boxes, lipstick boxes, skincare packaging, and other premium consumer goods

This solution is widely used in the cosmetics and daily consumer goods industries, where box appearance and consistency are critical to brand image.

Shipping Box / Mailer Box Solutions

For Shipping Boxes / Mailer Boxes, UBL provides dedicated machines designed specifically for airplane-style box structures commonly used in e-commerce logistics.

HL-Z15 Mailer Box Folding Machine (Standard Version)

Box type: Shipping Box / Mailer Box

Production speed: 720900 boxes/h

Footprint(L*W*H): Approx. 1900*1300*1800mm

Typical applications: E-commerce shipping boxes, mailer packaging boxes, subscription boxes, express delivery cartons

HL-Z30 Shipping Box Folding Machine (High-Speed Version)

For customers with higher throughput requirements, the HL-Z30 offers increased forming speed while maintaining folding precision.

Production speed: Up to 1200-2400 boxes/h

Footprint(L*W*H): Approx. 1930*1230*1960mm

Typical applications: High-volume e-commerce fulfillment centers and automated shipping lines

Rigid Box with Lid / 2-Piece Box Solutions

For Rigid Boxes with Lid (2-Piece Boxes), UBL offers glue-based forming solutions designed for precise folding and stable box structure.

HL-ZP20 Rigid Box with Lid Glue Spraying and Folding Machine

Production speed: 1500-1800 boxes/h

Footprint: Approx. 3300*1300*1900 mm

HL-ZP30 Rigid Box with Lid Glue Spraying and Folding Machine

Production speed: 1800-2400 boxes/h

Footprint(L*W*H): Approx. 3650*1250*1960mm

These machines are suitable for rigid packaging boxes used in:

Food packaging boxes (e.g., fruit boxes, pizza boxes)

Gift boxes and premium consumer packaging

Specialty retail packaging boxes

Custom Packaging Box Folding Solutions

If your packaging box structure does not belong to any of the above categories, UBL can still support you.

With strong in-house R&D capabilities, we design customized box folding machines based on your packaging box style, dimensions, and production requirements.

👉 Leave your information in the form below, and our engineers will contact you within 24 hours to evaluate your packaging box and propose the most suitable solution.

Cartoning Solutions

Cartoning is more than simply placing products into boxes.

An automatic cartoning machine integrates box opening, box forming, product insertion, and carton sealing into a single continuous process. Compared with manual or semi-automatic packing, cartoning ensures higher consistency, better sealing quality, and stable production efficiency.

UBL provides tailored cartoning solutions for different packaging box structures, each designed within specific size ranges and application scenarios. Our cartoning machines can operate independently or be integrated into a full automated packaging line.

Snap Lock Bottom Box Cartoning Solution

For Snap Lock Bottom / Auto-Lock Boxes, UBL recommends the HL-ZKC-02 Snap Lock Bottom Box Automatic Cartoning Machine.

This machine is capable of erecting snap lock bottom boxes, inserting products, and sealing cartons in one continuous operation, ensuring strong box structure and reliable packaging output.

Compatible box type: Snap Lock Bottom / Auto-Lock Box

Speed: 30–60 cartons/min

Machine size: L3500 × W1400 × H1800 mm

Typical applications:

E-commerce packaging such as hair dryer boxes, electric shaver boxes, coffee stick boxes, and other snap lock bottom packaging boxes

As long as the box structure is a snap lock bottom design and within the size range, the machine can be fully compatible.

Tuck End Box Cartoning Solution

For Tuck End Boxes (STE / RTE), UBL recommends the HL-ZC-G1 Servo Tuck End Box Cartoning Machine.

Designed specifically for tuck end cartons, this servo-driven cartoning machine delivers stable box opening, precise product loading, and neat tuck-end closing.

Compatible box type: Tuck End Box (Straight / Reverse Tuck End)

Speed: 50–60 pcs/min

Machine size: L3300 × W1250 × H1700 mm

Typical applications:

Cosmetics: foundation bottles, cushion compacts

Food products: compressed biscuits, cookies, chocolates

This solution is ideal for industries where carton appearance and packing accuracy are critical to brand image.

Glue-Sealed Box Cartoning Solution

For products requiring tamper resistance and one-time sealing, UBL provides high-speed glue-sealed cartoning solutions.

We recommend the HL-ZC-G2 High Speed Glue Spraying and Boxing Machine, designed for irreversible carton sealing using hot-melt glue.

Compatible box type: Glue-Sealed Box

Speed: 6,000–9,000 pcs/hour

Machine size: 6100 × 1800 × 2000 mm

Typical applications: Blind box toys, food packaging, disposable or anti-tamper packaging boxes

Once opened, these boxes cannot be resealed, effectively reducing tampering and return risks.

Vertical Cartoning Solution

For customers with limited factory space or special product orientation requirements, UBL also offers vertical cartoning solutions.

Recommended model: HL-ZC-G3 Vertical Cartoning Machine

Application advantage:Vertical loading structure saves floor space and suits products that must remain upright during cartoning

This solution is commonly chosen when workshop layout or product form limits the use of horizontal cartoning machines.

Bagging Packing Solutions

Bagging is a key step in secondary packaging, serving both product protection and brand presentation.

UBL provides automatic bagging solutions for a wide variety of products and packaging formats. Each bagging machine is designed to operate within defined bag and product size ranges, ensuring stable performance and consistent output.

Our bagging systems can be used as standalone machines or seamlessly integrated into a complete packaging line.

Prefabricated Bag Bagging

For products packaged in pre-made bags, UBL provides flexible bagging solutions designed for different production capacities and application scenarios. Our prefabricated bag bagging machines automatically open the bag, insert the product, and seal it with stable and consistent performance.

YH-MA61J Prefabricated Bag Bagging Machine

Designed for stable and flexible production environments.

Speed: 20–50 pcs/min

Machine size: 3075 × 2320 × 1465 mm

Typical applications:

Tea, coffee sticks, stick beverages, towels, biscuits, and other products requiring prefabricated bag packaging

This model is ideal for manufacturers seeking reliable automation with flexible product changeovers.

YH-A51D Automatic Pre-Made Bag Bagging Machine

Designed for higher output with a more compact footprint.

Speed: 800–1000 pcs/hour

Machine size: L2900 × W1300 × H1470 mm

Optional function: Vacuum sealing (for moisture protection and extended shelf life)

Typical applications:

Tea, coffee sticks, food snacks, towels, and moisture-sensitive products

With the optional vacuum feature, the YH-A51D is especially suitable for food and daily consumer goods that require enhanced protection during transportation and storage.

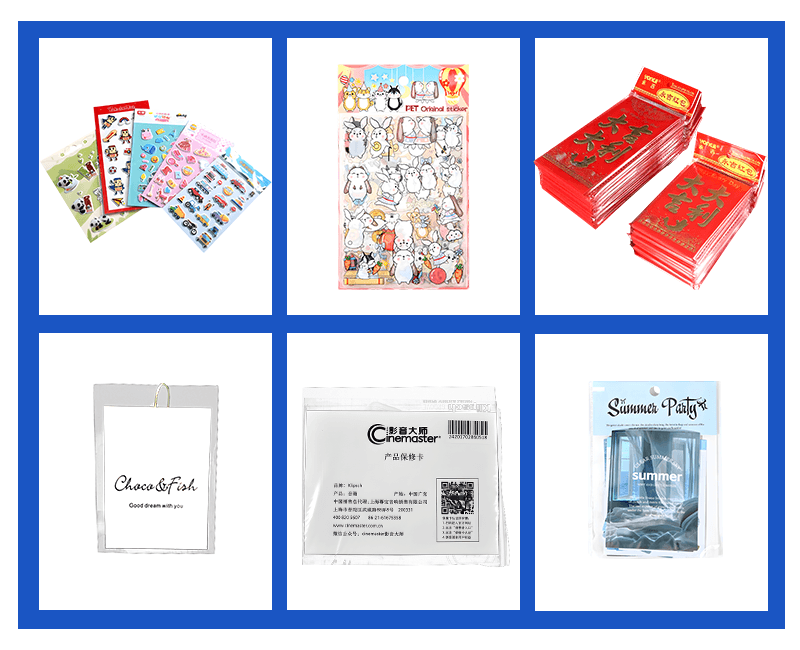

Adhesive Strip Bagging

For flat products that require simple, clean, and fast packaging, UBL recommends the YH-TA21G-35 T-Type High-Speed Bagging Machine.

This system uses bags with adhesive strips, making it ideal for products that do not require heat sealing.

Bag type: Adhesive strip bag

Speed: 20–50 pcs/min

Machine size: 3950 × 2825 × 1505 mm

Typical applications:

Cards, red envelopes, books, documents, paper products, and printed materials

This bagging solution is commonly used in stationery, publishing, and promotional packaging, offering neat appearance and high productivity.

Shrink Wrapping & Film Bagging

For premium products that require enhanced appearance and surface protection, UBL provides shrink wrapping solutions.

We recommend the YH-ZA11C-48 Four Corner Cutting Shrink Wrapping Machine, designed to wrap products with film and apply heat shrinking for a tight, glossy finish.

Packaging type: Film wrapping with heat shrink

Speed: 350–600 pcs/hour

Machine size: 2600 × 1420 × 1810 mm

Typical applications:

Bluetooth earphones, mobile phones, cosmetic compacts, skincare bottles, foundation and cushion boxes

Shrink wrapping not only protects the product from dust and scratches, but also enhances shelf appeal and perceived brand value, making it a popular choice for high-end consumer products.

Automatic bagging systems from UBL help you:

Protect products during storage and transportation

Improve packaging consistency and appearance

Reduce manual labor and packaging errors

Enhance brand image with professional, premium packaging

Whether you need prefabricated bagging, adhesive strip bagging, or shrink wrapping, UBL can deliver a solution tailored to your product and production requirements.

Apparel Folding & Packaging

Apparel folding and packaging automation simplifies garment handling by turning a traditionally labor-intensive process into a standardized and efficient workflow.

By simply placing garments onto the machine, the system automatically completes precise folding, followed by bagging and sealing, ensuring uniform presentation and reliable packaging quality.

UBL apparel folding machines can be flexibly connected with additional modules such as bagging and labeling, making them suitable for both standalone operation and fully automated packaging lines.

Standalone Clothes Folding

For customers who only require automatic garment folding, UBL recommends the SA-51A Single Station Clothes Folding Machine.

This compact machine focuses purely on folding, making it ideal for limited-space operations or entry-level automation.

Function: Automatic garment folding only

Machine size: 1160 × 880 × 800 mm

Typical applications:

T-shirts, lightweight tops, basic apparel items

The SA-51A is a cost-effective solution for businesses looking to improve folding consistency while keeping investment and footprint to a minimum.

Integrated Folding & Bagging

For higher efficiency and reduced manual handling, UBL recommends the FC-252T Automatic Set Garment Folding and Packaging Machine.

This system automatically folds garments and transfers them directly into bags for sealing, creating a clean and professional packaging output.

Function: Automatic folding, bagging, and sealing

Speed: 350–550 sets/hour

Machine size: 4800 mm × 1200 mm × 1650 mm

Compatible garments: Jackets, T-shirts, hoodies, and similar apparel items

This solution is widely used in apparel manufacturing, e-commerce fulfillment, and uniform production, where speed and consistency are critical.

UBL also provides dedicated folding solutions for medical protective garments, ensuring standardized folding suitable for healthcare and controlled environments.

Below, you can explore a complete apparel folding and packaging line, covering everything from garment feeding to ready-to-ship packages—with minimal to no manual intervention.

Solutions by Industry

Consumer goods packaging must balance presentation quality, efficiency, and supply chain stability. Smart packaging solutions adapt to frequent SKU changes while ensuring consistent packaging and inspection for cosmetics and household products.

E-commerce operations face fluctuating order volumes, tight delivery windows, and labor pressure. Automated packaging solutions improve order accuracy, speed, and flexibility for parcels, express bags, and mixed orders

Packaging for hardware and industrial components requires accuracy, durability, and protection. Automated solutions support precise counting, reinforced packaging, and stable handling for parts, components, and bulk goods.

Pharmaceutical packaging demands strict control over compliance, traceability, and process reliability. Intelligent, GMP-aligned packaging and inspection solutions support safe, regulated production for pharmaceuticals and medical products.

Apparel manufacturers and fulfillment centers require fast, uniform, and space-efficient folding and packaging. Automated solutions deliver consistent presentation and higher throughput for garments, uniforms, and workwear.

High-volume food and beverage production demands hygienic, consistent, and high-speed packaging. Intelligent packaging solutions support product freshness, regulatory compliance, and stable output across beverages, snacks, and frozen foods.

Core Solution Capabilities

- Automated Bagging & Boxing:Flexible automated solutions for bagging and boxing a wide range of products. Designed to handle different sizes, materials, and packaging formats with consistent speed and accuracy.

- Counting, Weighing & Sorting:High-precision counting and weighing technologies ensure accurate packaging for small parts, food products, and industrial components, reducing errors and rework.

- Labeling, Coding & Inspection:Integrated labeling, coding, and inspection systems ensure packaging accuracy, traceability, and compliance with industry and regulatory requirements.

- End-of-Line Packaging Automation:From case packing to palletizing, end-of-line automation improves throughput, reduces manual handling, and stabilizes final-stage packaging operations.

- Modular & Scalable Line Design:Modular system architecture allows packaging lines to scale with production growth and adapt quickly to new products or packaging requirements.

- ERP / MES System Integration:Smart packaging solutions designed to integrate seamlessly with ERP and MES systems, enabling real-time data collection, traceability, and production visibility.

FAQ

Below are answers to some of the most common questions about smart packaging solutions, customization, and system integration.

Can packaging solutions be customized for different products?

Yes. Smart packaging solutions are designed to be highly flexible and can be customized based on product size, material, packaging format, and production requirements.

Can the packaging system integrate with ERP or MES platforms?

Yes. Modern packaging systems support seamless integration with ERP, MES, and other production management systems, enabling real-time data collection and process visibility.

How long does it take to implement an automated packaging solution?

Implementation timelines vary depending on project complexity, line configuration, and customization requirements. Most solutions can be deployed in stages to minimize production disruption.

Are these solutions scalable as production grows?

Yes. Modular system design allows packaging lines to expand or reconfigure easily as production volume increases or product requirements change.

Have more questions or specific requirements?

Share your product details and production needs using the form below. Our engineers will review your application and propose a packaging solution tailored to your production line.

Contract Us

At UBL Intelligent Packaging Group, we are committed to providing you with high-quality intelligent packaging solutions and professional services.

Whether you have inquiries about products, need customized solutions, or require after-sales support, our team is ready to assist you.