Thanksgiving Doesn’t Break People — It Breaks Your Packaging Line

Alyssa/ November 26, 2025 Return

Have you ever noticed how every factory looks calm… until Thanksgiving gets close? Orders multiply, customers rush, deadlines tighten, and every department starts shaking—but nothing collapses faster than the packaging line. Not the production machines, not the suppliers, not the raw material storage. It’s always the packaging line that breaks first.

And you know that moment.

The moment your folding machine hesitates.

The moment your cartoning machine jams on a slightly crooked box.

The moment your bagging machine seals one bag wrong and suddenly every worker is shouting.

Suddenly Thanksgiving season doesn’t feel warm or grateful—it feels like a countdown to disaster.

If you’ve ever stood there watching products pile up behind your packaging machine while your chest gets tight and your stomach sinks, then trust me: I know exactly what kind of pressure is killing you.

Because Thanksgiving doesn’t create chaos.

Thanksgiving exposes the chaos you’ve been ignoring.

During normal months, your manual packaging might barely survive. Workers move fast, fix errors, patch mistakes, and somehow keep the packaging line alive. But Thanksgiving? Thanksgiving takes your small problem and turns it into a crisis. One tiny hesitation in the folding machine becomes an avalanche. One misfolded box in the cartoning machine becomes a full-line shutdown. One failed seal in the bagging machine becomes a chain reaction of delays, complaints, and lost orders.

Here’s the real truth:

Manual packaging cannot survive holiday peak season.

Not during Thanksgiving.

Not during Black Friday.

Not during Christmas.

Humans cannot fold boxes with machine-level precision for 8–12 hours. Humans cannot match the speed of a packaging machine that never sleeps, never hesitates, never gets tired. When your entire end-of-line packaging depends on human hands, you are basically gambling with your entire holiday output.

And during Thanksgiving, you WILL lose that gamble.

Factories in the US and UK already know this. That’s why many of them upgrade their folding machine, cartoning machine, and bagging machine before the holiday chaos even starts. They choose automated packaging machines—not because they want to replace workers, but because workers cannot carry the weight of Thanksgiving alone.

This is why UBL’s machines have become the “holiday survival kit” for so many factories.

A folding machine from UBL forms clean, consistent creases—even when orders triple.

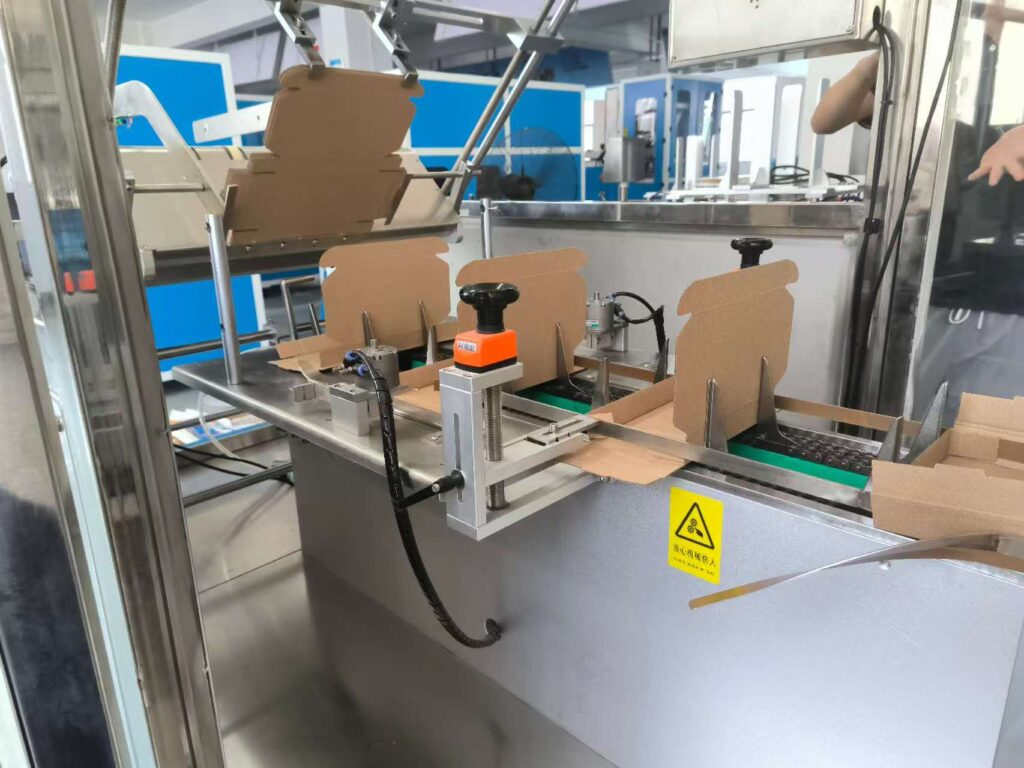

A cartoning machine like UBL’s HL-Z15 forms boxes at high speed without choking on imperfect edges.

A UBL bagging machine seals bags perfectly, even during those stressful, overworked hours when humans usually make mistakes.

UBL machines don’t panic, don’t get tired, don’t ask for holidays, and don’t collapse when the pressure spikes.

And during Thanksgiving, that stability is everything.

Because if you don’t upgrade your packaging line, here’s exactly what will happen:

Your bottleneck will explode.

Your overtime will skyrocket.

Your workers will burn out.

Your shipments will be late.

Your customers will complain.

Your brand rating will drop.

And you’ll spend the whole holiday season wondering why the packaging line hates you.

But if you stabilize the last meter with automated packaging?

Suddenly the entire factory flows.

The stress disappears.

The orders get fulfilled.

And Thanksgiving finally feels like a season you can survive—not a war you are destined to lose.

So tell me honestly:

What usually breaks first in your factory when Thanksgiving hits?

If you tell me, I can already guess the exact moment everything starts falling apart.