The Last Meter of the Factory Line — Where Everything Falls Apart

Alyssa/ November 25, 2025 Return

Have you ever stood at the end of your production line and felt that sinking, stomach-twisting moment when everything collapses right at the packaging machine? The folding machine slows down, a box jams inside the cartoning machine, the bagging machine suddenly mis-seals a bag—and in ten seconds your entire production line feels like it’s choking to death. It’s the kind of moment that makes even experienced managers want to grab their head and yell.

And here’s the painful truth: the last meter of your packaging line is often the most dangerous place in the entire factory. It looks simple, it looks harmless, but one mistake in the packaging machine can destroy the output of your whole day. A tiny tilt in a folding box machine becomes a major jam. A half-formed box in the cartoning machine becomes a backlog. A weak seal in the bagging machine becomes a customer complaint. If you have ever felt your chest tighten watching products pile up behind the packaging line, you already know exactly what I’m talking about.

The reason this keeps happening is brutally simple: manual packaging cannot survive high-speed production. Humans cannot repeat the same fold 3,000 times without errors. They cannot maintain consistent packaging quality when tired. They cannot become automated packaging machines no matter how hard they try. Fatigue wins. Chaos wins. And your factory loses.

If the rest of your production line is automated but your final packaging is still manual, you are building a time bomb. Not metaphorically—literally. Every day the packaging line becomes your bottleneck. Every day your output depends on human fatigue. Every day your folding machine, cartoning machine, and bagging machine fight against the limits of manual support. And eventually, the entire packaging line collapses.

This is why more factories in English-speaking markets are upgrading their end-of-line packaging machine first. Not the expensive upstream equipment. Not the flashy automation. The packaging machine. Because when your folding machine, cartoning machine, and bagging machine run smoothly, the whole factory finally breathes.

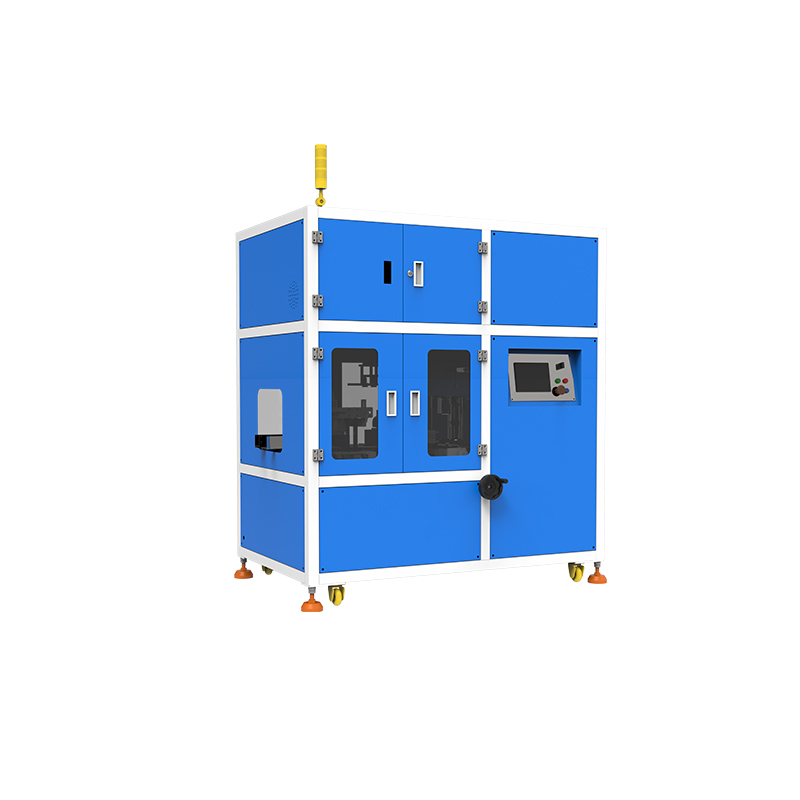

When factories replace manual folding with an automated folding machine—like UBL’s high-speed folding machine designed for stable packaging—the fold becomes clean every single time. When they switch to an automated cartoning machine—like UBL’s HL-Z15—it forms boxes without hesitation, without errors, without “bad days.” When they add a reliable bagging machine, sealing becomes consistent instead of stressful.

The packaging line stops being a battlefield and becomes the backbone of the factory.

If you keep ignoring the bottleneck, things WILL get worse. More delays. More overtime. More wasted materials. More complaints. More lost orders. More nights where you stare at your packaging line and think, “Why is this happening again?”

But the moment you automate your packaging line, something changes. The bottleneck dissolves. The pressure lifts. The folding machine stops fighting. The cartoning machine stops choking. The bagging machine stops “acting stubborn.” And your entire production line finally runs the way it was meant to run.

So let me ask you this honestly—

Is your factory being destroyed by its own packaging line?

Tell me what’s happening in your last meter. I guarantee you’re not the only one.